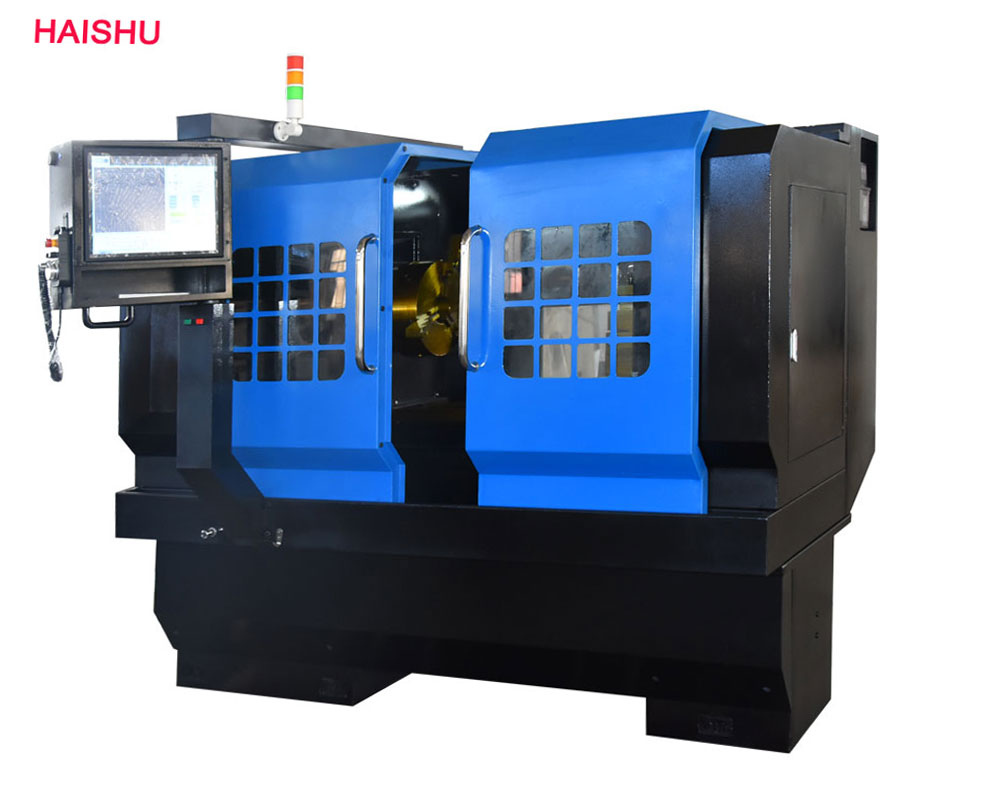

New wheel repair lathes is a kind of wheel CNC lathe specially used for refurbishing or repairing automobile wheels. The earliest form of this kind of lathe was an ordinary horizontal lathe with special fixtures. Then use ordinary tools for turning bit by bit to complete the final repair process. After the turning is completed, the process of cleaning, drying, painting, and drying will be used. Achieve a rainbow color effect during driving. In order to achieve better results, everyone still uses electroplating for the beauty process of car wheels. If the car is deformed, we will also use a dedicated shaping machine to correct the outer circle of the. Then use the new wheel repair lathes to process.

In the beginning, the number of cars was scarce, and the manual mode could meet the demand. But with technological development, the number of cars has increased. More and more people want to beautify their cars, in addition to decorating the interior and changing the paint. There is also a great demand for the color change and deformation of automobile wheels. The manual mode is gradually not suitable for the current development speed. Therefore, HAISHU invented a CNC new wheel repair lathe, which can also be called a CNC wheel repair machine.

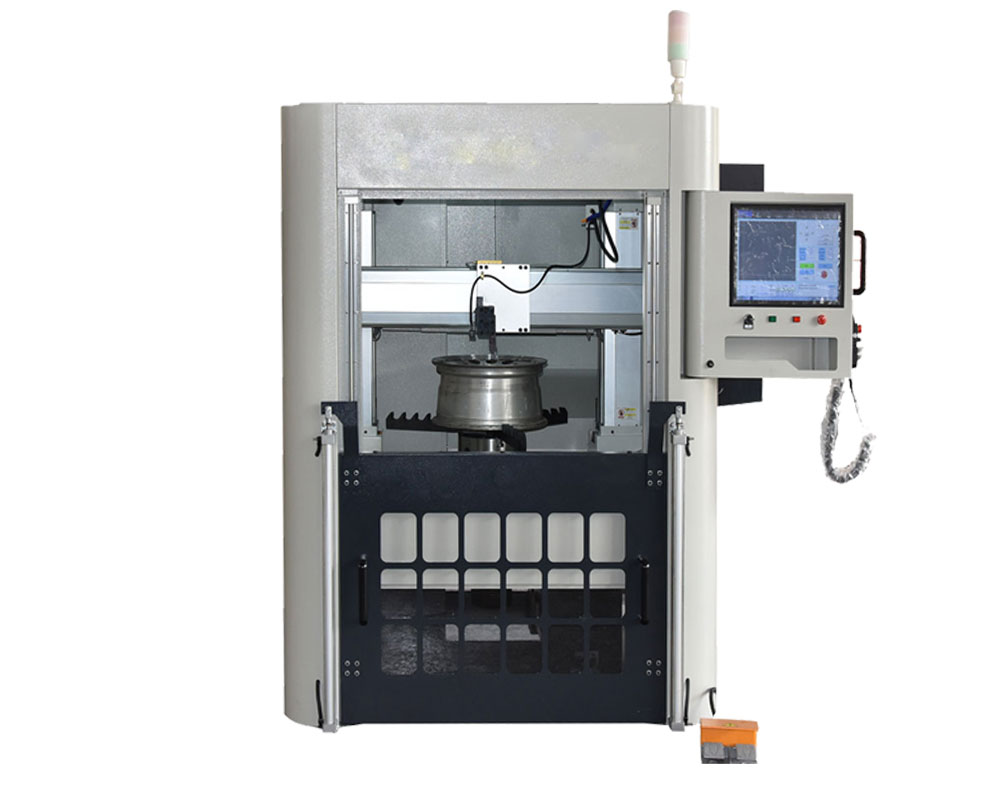

Our CNC wheel repair machine adopts a fully automatic mode. Laser detection is possible, and it only takes 10-15 seconds to complete the detection. The traditional manual mode takes 10-20 minutes to complete this process, depending on the proficiency of the operator. HAISHU‘s vertical new wheel repair lathes not only improve efficiency but also reduces the requirements for operator experience. They can master the operation methods and skills within 30 minutes.

Let’s Explain Haishu’s Wheel Repair Lathe in Detail.

First of all, HAISHU’s wheel lathe adopts a computer system-based architecture and is equipped with special software for wheel repair. Completely independent research and development can provide customers with remote services and free upgrades at any time, we promise to permanently upgrade free of charge. The dedicated software for this CNC wheel lathe is divided into six sections. Operation interface, optimization interface, program interface, parameter interface, processing interface, and modification interface. Different processing requirements can be realized through different interfaces, and customers can adjust through the interface at any time, which is completely automated and very user-friendly.

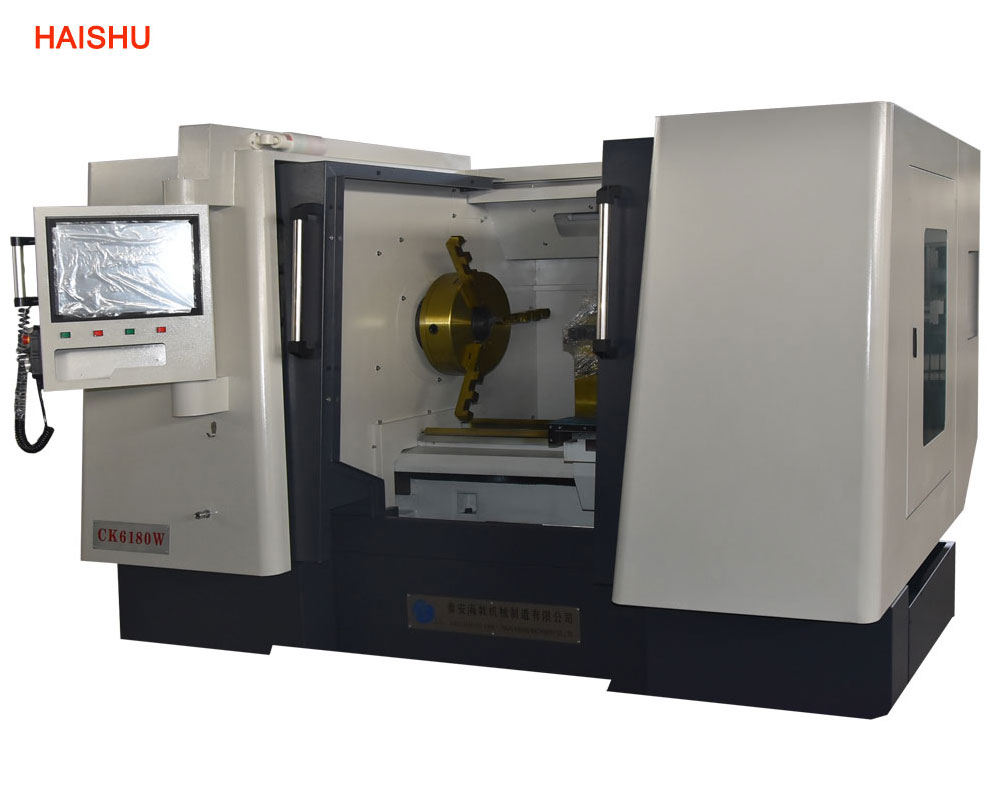

The second is to better realize the surface finish of the wheel, we adopt the spindle unit structure, which has high stability and increased structural strength. It can increase stability and rigidity when repairing larger wheels. Secondly, we have also optimized the transmission structure. The traditional new wheel repair lathes adopt a hard track and a two-point one-line structure. The ordinary horizontal lathe structure generates a large centrifugal force in the wheel rotation type. Causes different ripples after the wheel is repaired. HAISHU’s wheel repair machine adopts a vertical structure, which can rotate smoothly with the help of gravity. In addition, we have adopted a linear rail ball mode on the drive shaft, which has fast-moving speed and high machining accuracy. The characteristics of wear resistance and easy maintenance are very obvious.

We have two Z-axis and one X-axis for the entire driveshaft. The structure of the door frame further enhances the processing finish, which is unmatched by other machine tools. Moreover, the base of our wheel repair machine is made of all cast iron, which has sufficient weight and a stable chassis.

Third, everyone also has very high requirements for the safety of the wheel repair machine. In order to increase the safety of the operators, the entire mobile door uses toughened glass, and the door opens and closes fully automatically. Large cylinders are used on both sides, so an adult can’t let the door open casually. And we have set up an alarm device. Once the door is opened during processing, the new wheel repair lathes will immediately issue an alarm and stop running.

Fourth, the maintenance of the new wheel repair lathes during use is also very important. The traditional manual way to lubricate the guide rail is no longer in line with the customer’s operating habits. We adopted a fully automatic lubrication method for the vertical wheel repair machine. The machine will automatically lubricate within the set time, which prolongs the service life of the repair machine. In addition, we have added an air source for our customers. After the wheel is repaired, the aluminum chips can be blown off with air, which is very convenient.

Fifth, the biggest feature of our vertical wheel lathe is that it can use laser probes and contact probes at the same time to meet the requirements of different customers for different wheel processing. This is a unique upgrade part of our wheel lathe. The laser probe can complete the detection in 15 seconds, and the contact probe can detect the wheel with a relatively large slope, and the third detection method is to directly use the tool to detect, which is the most accurate and our newly developed technology.

sixth. Our probes can be mounted on different tool holders, such as gang tool structure, manual tool holder structure, and electric tool holder structure. Different methods of tool change can be carried out according to the different requirements of customers, and the humanization and modernization are very comprehensive.

seventh. Our service team consists of seven people, including two electrical engineers, two mechanical engineers, and three technical training engineers, which can provide 24×7 hours of technical service and support. We can also provide door-to-door service, but this service has been temporarily terminated due to the epidemic. We will reopen this service after the epidemic is over.

eighth. If you think these are not enough, there is no problem. We also provide tailor-made services. Repair lathe for your exclusive new wheel. Our four-person design team can design drawings and 3D animations for you within 3 days. If you want to add other functions, our software development department can also customize the functions for you. You can customize different shapes and different functions. We will do our best to meet the different requirements of customers.

About Taian HAISHU

Tai’an Haishu Company is a company specializing in the design, research and development, production, and sales of wheel lathes. In the 12 years since our company was established, it has had trade transactions with more than 90 countries around the world. And there are professional sales agent teams in different regions. You can get our wheel repair lathe directly through the agent. And the agent will provide you with professional technical services and training. At the same time, we are now recruiting countries and regions without agents to join our team. Hope to provide you with perfect products and services.