1. What is Rim Repair Equipment?

Rim repair equipment primarily refers to CNC wheel hub repair machines (machine de réparation de roues)designed to address scratches and damage on automotive alloy wheels. These advanced machines are essential for restoring wheel hubs to a like-new condition while ensuring they comply with factory specifications. By utilizing wheel repair machine (macchina per la riparazione delle ruote), vehicle owners can maintain their wheels’ aesthetic appeal and safety, ultimately preserving the vehicle’s overall value.

1.1 Why is Rim Repair Equipment Important?

- Restoration of Aesthetic Appeal: Rim repair equipment (휠 수리 기계) restores alloy wheels’ shiny, polished look, enhancing the vehicle’s appearance.

- Safety Compliance: Ensuring wheels meet factory data standards is critical for vehicle safety.

- Cost-Effective Solution: Repairing damaged rims is often cheaper than replacement, providing significant savings for car owners.

2. How Does Rim Repair Equipment Work?

alloy wheel repair machine (wielen reparatie machine) operates through various advanced technologies that facilitate the detection and repair process.

2.1 What Are the Key Functions of Rim Repair Equipment?

- Surface Detection: CNC wheel hub repair machines identify the exact damage on the wheel surface.

- Path Optimization: The system generates a machining path based on detected data.

- CNC Program Output: The optimized path is converted into a CNC machining program for execution.

2.2 What Types of Rim Repair Equipment Are Available?

- Wheel Repair Lathes (máy sửa chữa bánh xe): Specialized machines for reshaping and smoothing wheel surfaces.

- Aluminum Wheel CNC Lathes(Felgen reparatur maschine): Machines specifically designed for aluminum alloy wheels, ensuring precise repairs.

- Alloy Repair Machines: These machines focus on repairing various alloy wheel types, providing flexibility in service offerings.

3. What Detection Methods are Used in Rim Repair Equipment?

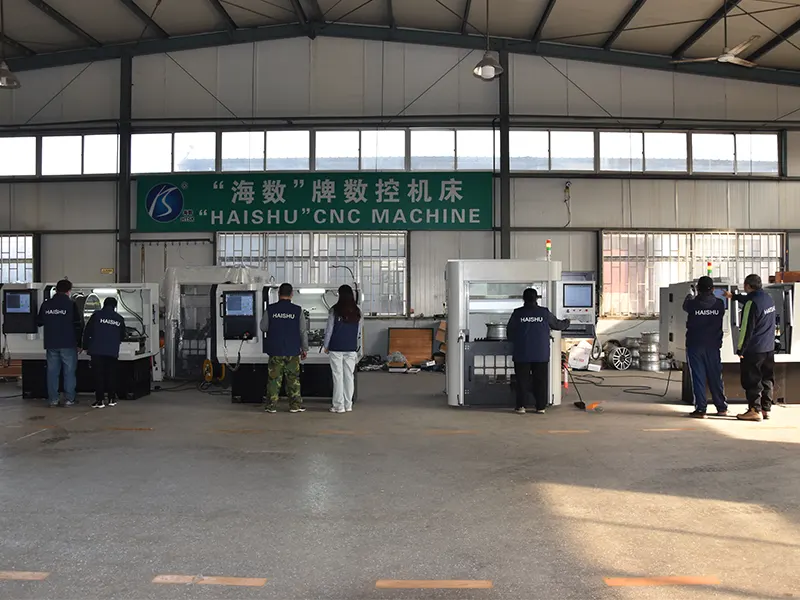

Tai’an Haishu has developed innovative detection methods that set their wheel CNC lathe apart in the industry.

3.1 What Are the Four Detection Methods?

- Laser Detection:

- Speed: Completes detection in just 15 to 30 seconds.

- Applicability: Highly versatile, suitable for various wheel hub designs.

- Probe Detection:

- Method: Requires physical contact with the wheel hub surface.

- Time-Consuming: Detection time varies based on the size and shape of the wheel.

- Automatic Tool Detection:

- Accuracy: Higher precision than probe detection, as it minimizes tilting and bending.

- Direct Data Input: Inputs data straight into the wheel hub repair system for efficiency.

- Manual Tool Detection:

- Complex Shapes: Designed for the most intricate wheel hub forms.

- Highest Accuracy: While it takes the longest, it provides the most precise measurements.

3.2 How Do These Detection Methods Benefit Users?

- Efficiency: Quick detection methods like laser detection save time, enhancing overall productivity.

- Precision: Automatic tool detection ensures high accuracy, reducing the risk of errors during the repair process.

- Versatility: Multiple detection options allow users to select the best method based on specific wheel characteristics.

4. How is the Machining Process Optimized in The Aluminum Wheel CNC lathe?

One of the standout features of advanced rim repair equipment is its ability to optimize the machining process.

4.1 What Are the Optimization Features?

- Automatic Optimization:

- User-Friendly: With just one click, users can optimize the machining path for smoother surfaces.

- Time-Saving: Reduces the time required for manual input and adjustments.

- Manual Optimization:

- Customization: Allows skilled users to adjust machining paths according to their preferences.

- Flexibility: Offers greater control over the final outcome, especially for complex shapes.

4.2 How Does Path Optimization Enhance Efficiency?

- Reduced Errors: Automatic optimization minimizes the chances of human error during programming.

- Increased Productivity: Faster program outputs lead to higher throughput in repair operations.

- Improved Accuracy: Precise machining paths ensure that the repairs are effective and long-lasting.

5. What Are the Benefits of Using Tai’an Haishu’s Rim Repair Equipment?

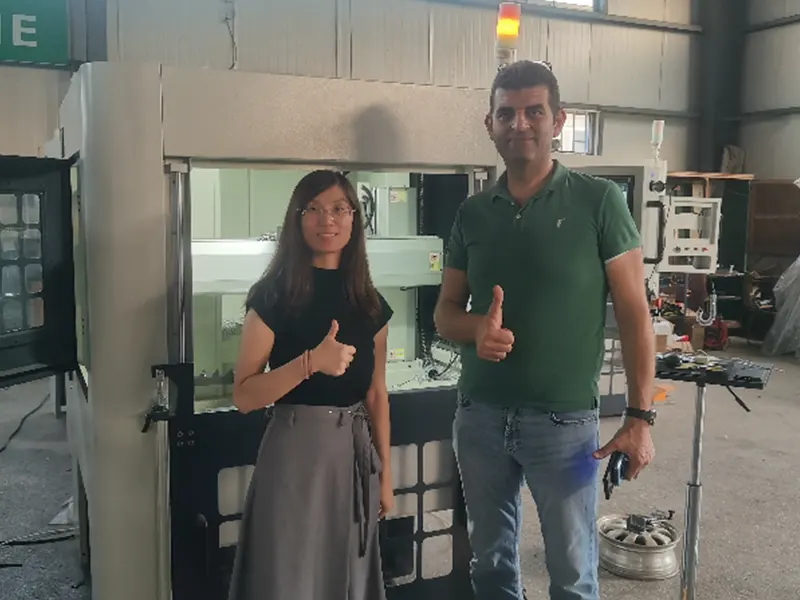

Choosing Tai’an Haishu’s rim repair equipment offers numerous advantages for automotive repair businesses.

5.1 Why Choose Tai’an Haishu?

- Innovative Technology: The incorporation of advanced detection methods and CNC programming sets their machines apart.

- User-Friendly Design: The machines are designed to be intuitive, making them accessible even to beginners.

- Comprehensive Support: Tai’an Haishu provides extensive training and customer service to ensure users can maximize the benefits of their equipment.

5.2 How Does Tai’an Haishu Ensure Quality?

- 23 Years of Experience: With over two decades in the industry, they have honed their manufacturing and service capabilities.

- Global Partnerships: Collaborating with over 60 partners worldwide ensures a broad understanding of market needs and customer preferences.

- OEM/ODM Services: Customization options for language, voltage, appearance, and branding cater to a diverse clientele.

6. How Does Rim Repair Equipment Impact the Automotive Repair Industry?

The introduction of advanced rim repair equipment has significantly transformed the automotive repair landscape.

6.1 What Trends Are Emerging in Rim Repair?

- Increased Demand for Efficiency: As repair shops seek to improve turnaround times, the need for innovative equipment rises.

- Focus on Sustainability: Repairing rather than replacing wheels contributes to environmental sustainability.

- Technological Advancements: Continuous improvements in CNC technology enhance the precision and capabilities of rim repair machines.

6.2 How Can Businesses Benefit from Rim Repair Equipment?

- Cost Savings: Investing in high-quality rim repair equipment reduces long-term costs associated with wheel replacements.

- Enhanced Service Offerings: Repair shops can expand their services to include rim repair, attracting more customers.

- Competitive Advantage: Advanced technology positions businesses as leaders in the automotive repair industry.

7. Conclusion: The Future of Rim Repair Equipment

Rim repair equipment is an essential part of maintaining the safety, aesthetics, and value of vehicles. With innovative solutions like those from Tai’an Haishu, automotive repair shops can provide high-quality wheel repair services efficiently and effectively.

7.1 Why Invest in Rim Repair Equipment?

- Long-Term Benefits: Investing in advanced aluminum wheel repair machine pays off through increased customer satisfaction and loyalty.

- Visit Our Factory: We invite all potential customers to visit our facility to see firsthand the quality and capabilities of our aluminum wheel repair machines (tekerlek onarım makinesi) and CNC technology.

By choosing Tai’an Haishu’s rim bending machine, you are investing in a future of efficiency, quality, and innovation in the automotive repair industry. Your inquiries are always welcome as you explore the best solutions for your wheel repair needs.