What Innovations Does the HAISHU CKL22Q Wheel Reconditioning Lathe Offer?

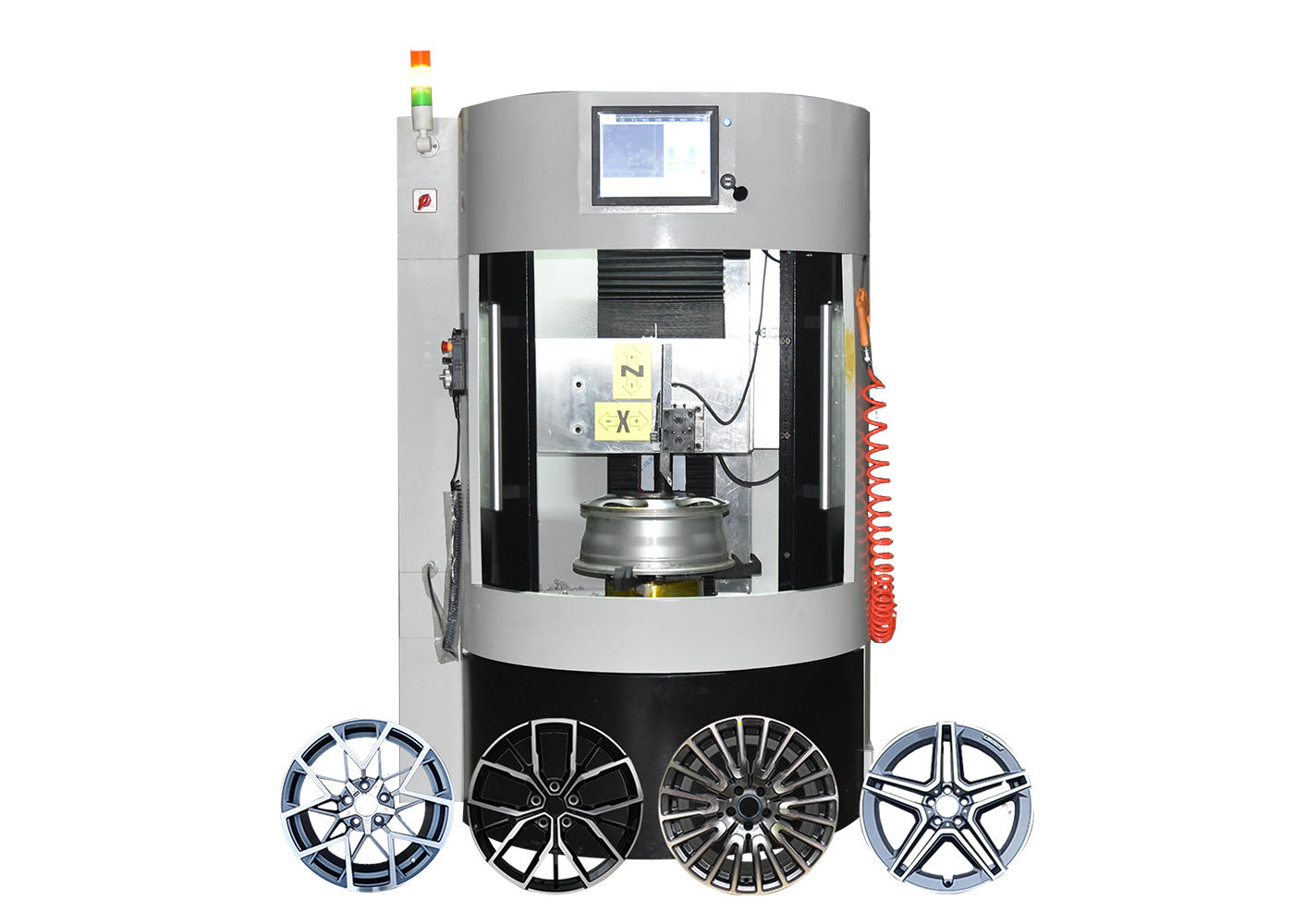

The HAISHU CKL22Q Wheel Reconditioning Lathe is at the cutting edge of wheel refurbishment technology. This wheel CNC machine is designed with a vertical structure, with its Z-axis perpendicular to the ground. This configuration allows wheels to be mounted horizontally on the chuck, which is particularly beneficial for larger wheels as it effectively neutralizes a significant portion of the centrifugal force. The design leverages the wheel’s own weight to ensure stable and smooth operation, enhancing the overall performance and stability of the Tire rim repair lathe.

How Does the CKL22Q Wheel Reconditioning Lathe Achieve High Precision and Speed?

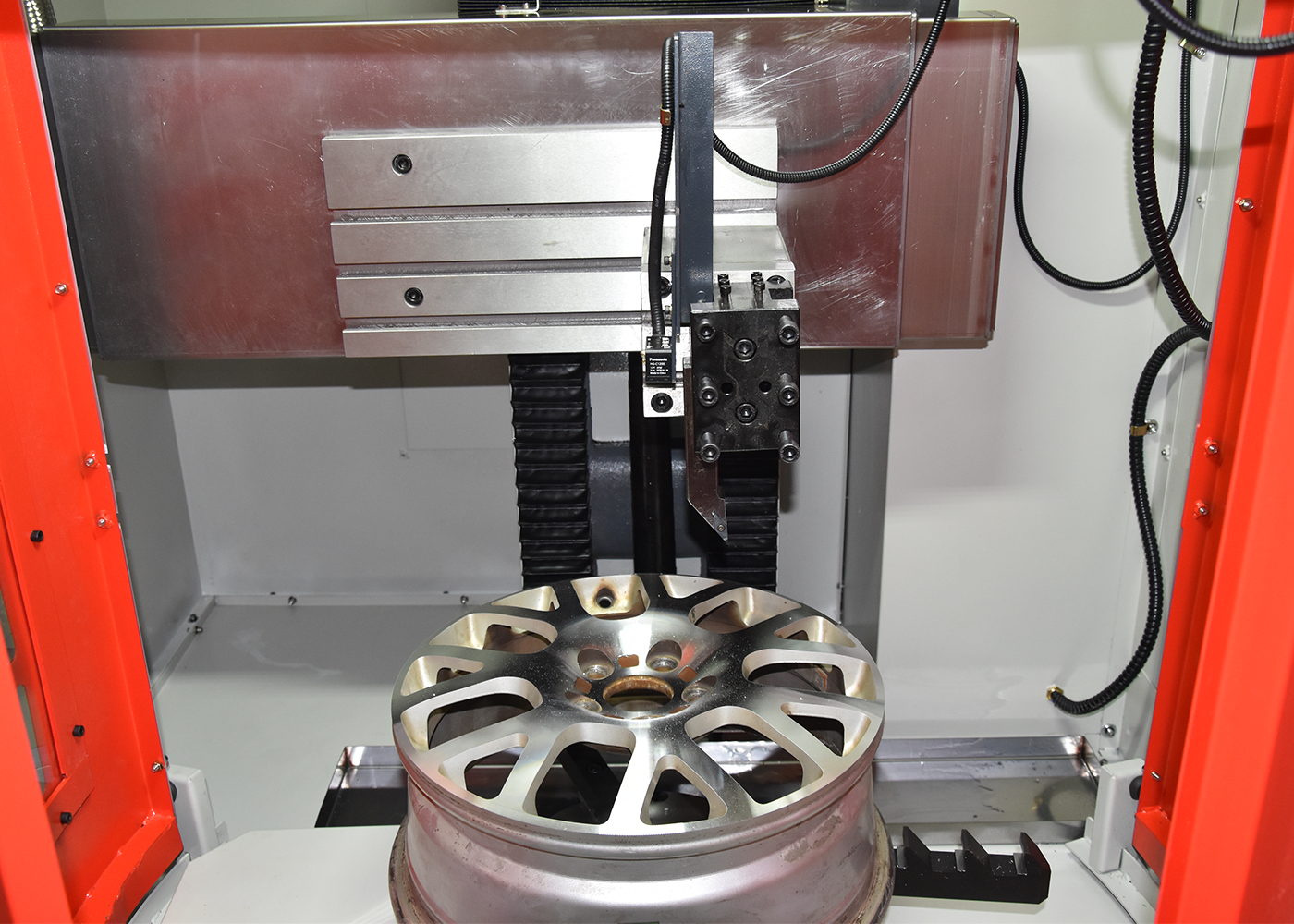

The CKL22Q Rim restoration machine features an advanced linear rail system equipped with ball bearings, ensuring rapid and smooth movement. This system is especially effective when working with aluminum alloy materials. By utilizing HAISHU’s proprietary PCD cutting blades, this wheel repair lathe is capable of achieving finishes close to mirror quality, with a surface roughness above 1.6, making it a leader in precision wheel repair.

What Advanced Features Does the CKL22Q Wheel Reconditioning Lathe Include?

To increase efficiency and precision in wheel repair, the CKL22Q Wheel Reconditioning Lathe is equipped with a 17-inch touchscreen and incorporates multiple detection methods including laser and probe detection. Laser detection is particularly popular among users for its ability to complete scans in about 15 seconds, significantly faster than probe detection. This feature makes the CKL22Q not just a wheel repair machine but a highly advanced wheel refurbishment machine that simplifies the detection of imperfections on the wheel surface.

How User-Friendly is the CKL22Q Wheel Reconditioning Lathe?

The HAISHU CKL22Q Alloy wheel refurbishing lathe offers a range of one-touch functions, such as one-touch detection, one-touch tool setting, one-touch optimization, and one-touch CNC program generation, greatly simplifying the operation process. Additionally, the machine includes a three-color light display and a handheld wheel, enhancing the operator’s ability to monitor and control the machine effectively from up close. This focus on user-friendly design reinforces the CKL22Q’s position as a top choice for professionals in the wheel refurbishment industry.