What is the Process of Wheel Repair with Tire?

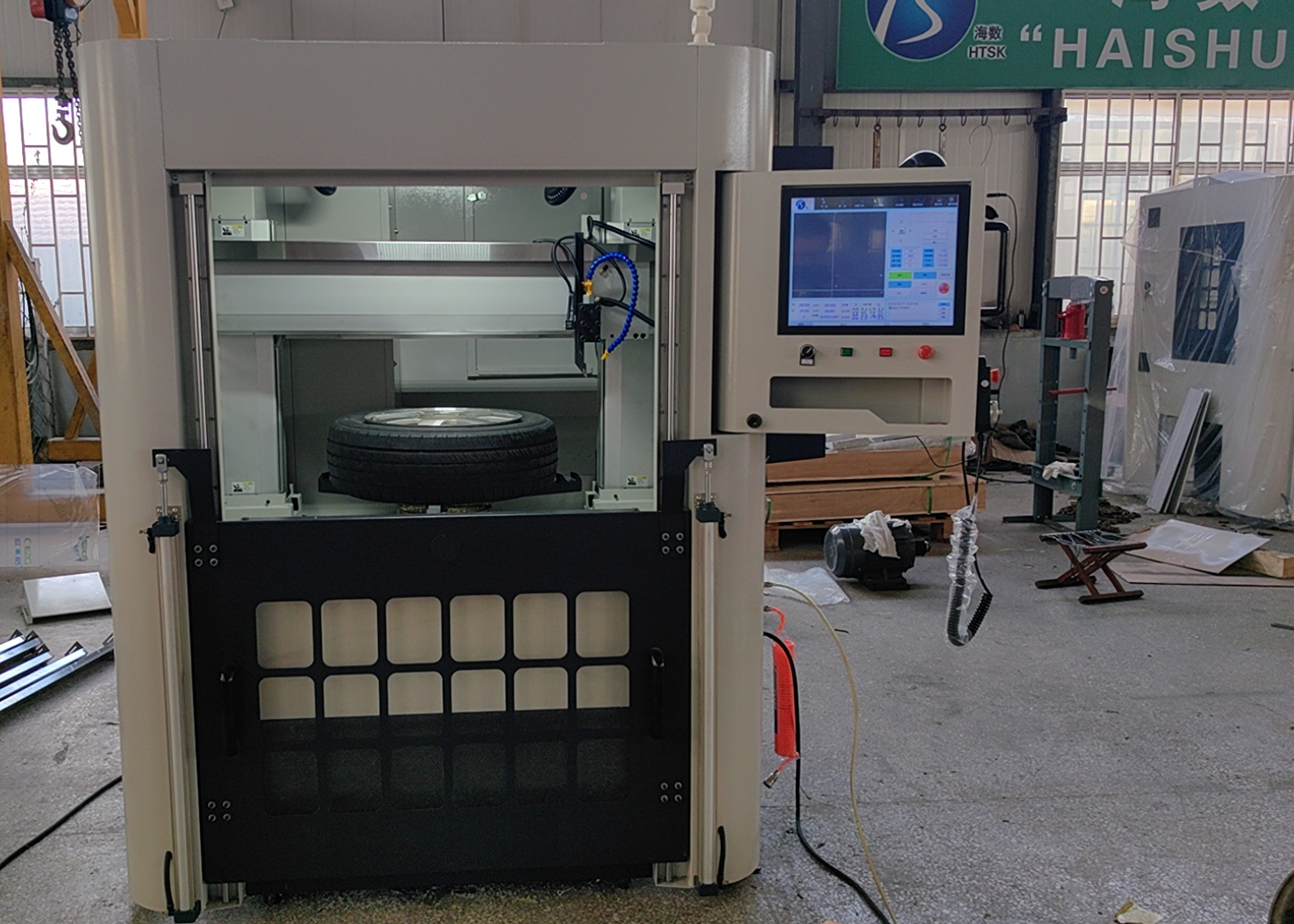

With the development of the times, the demand for efficient and precise wheel hub repair with tires is increasing. Traditionally, the process involved removing the wheel hub, placing it on a tire changer to remove the tire, then using a wheel straightening machine for correction, and finally using a wheel repair lathe for CNC machining. However, a more efficient and quicker method is what most users now seek. Today, we will discuss how HAISHU Company’s wheel repair lathe allows users to repair wheel hubs with the tires still attached.

How Does Wheel Repair with Tire Work?

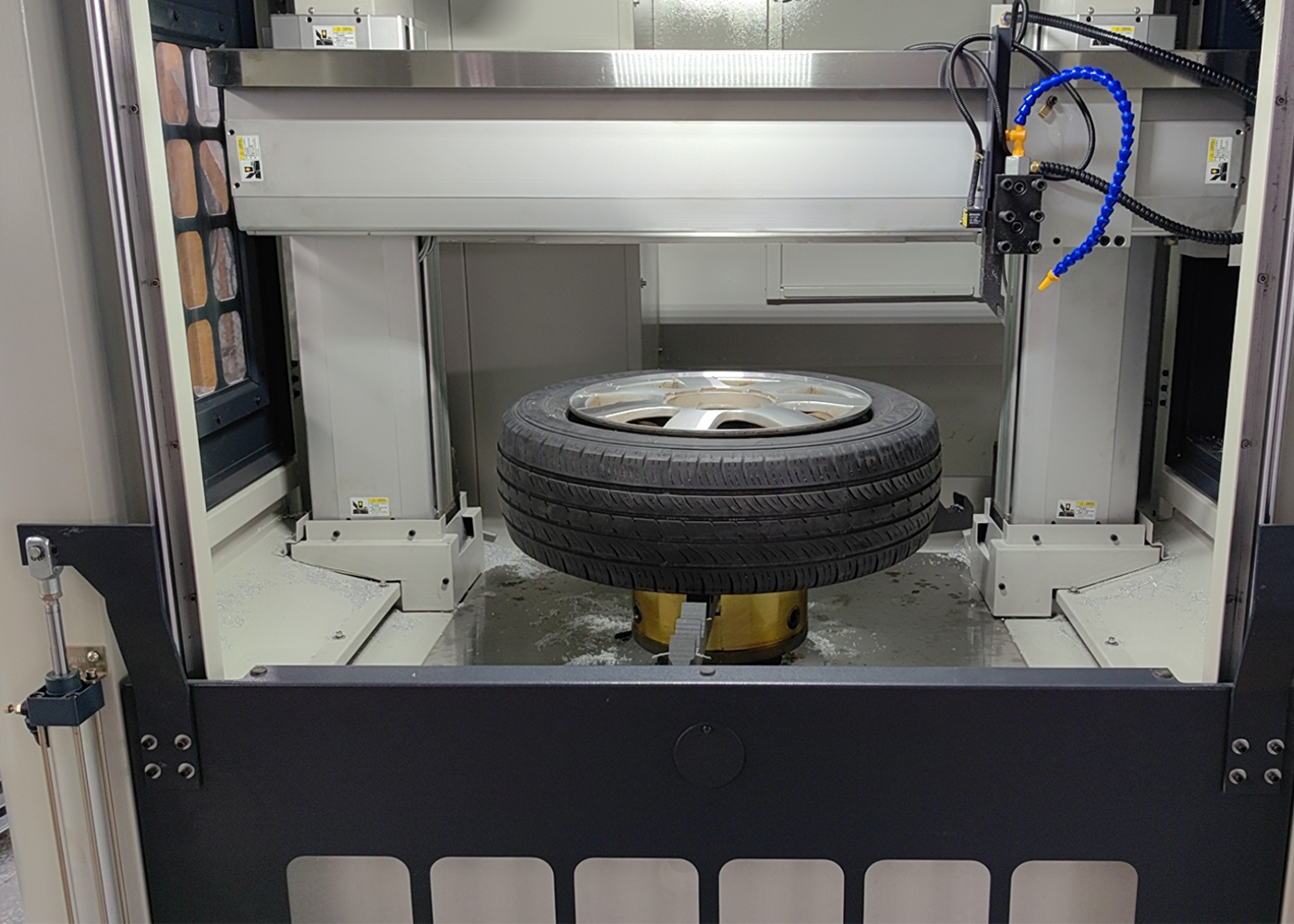

For wheel hubs that have only suffered minor scratches and have not been deformed, users at repair shops or 4S stores can directly remove the wheel hub and deflate the tire. After a simple cleaning, the wheel hub can be directly placed on an alloy wheel repair lathe for processing. However, this requires the wheel CNC machine to meet certain high standards. Firstly, it needs a relatively large turning diameter since the wheel hub itself is not very large, but with the tire attached, the overall size exceeds that of the hub. Therefore, a large turning diameter is necessary. HAISHU has specifically developed a vertical wheel repair lathe designed for large-sized wheel hubs and wheels with large tires.

Why Choose Vertical Structure for Wheel Repair with Tire?

The vertical structure allows the wheel hub to be placed flat on the fixture. Due to the large diameter of the tire, the centrifugal force is also significant when it rotates. Thus, placing the wheel hub flat helps counteract the centrifugal force through gravity. Additionally, the machine requires high rigidity. To meet this demand, HAISHU uses a double-column structure, forming a gantry-style setup that enhances the rigidity of the wheel repair machine, satisfying the need for large spans and high rigidity.

What Are the Precision Requirements for Wheel Repair with Tire?

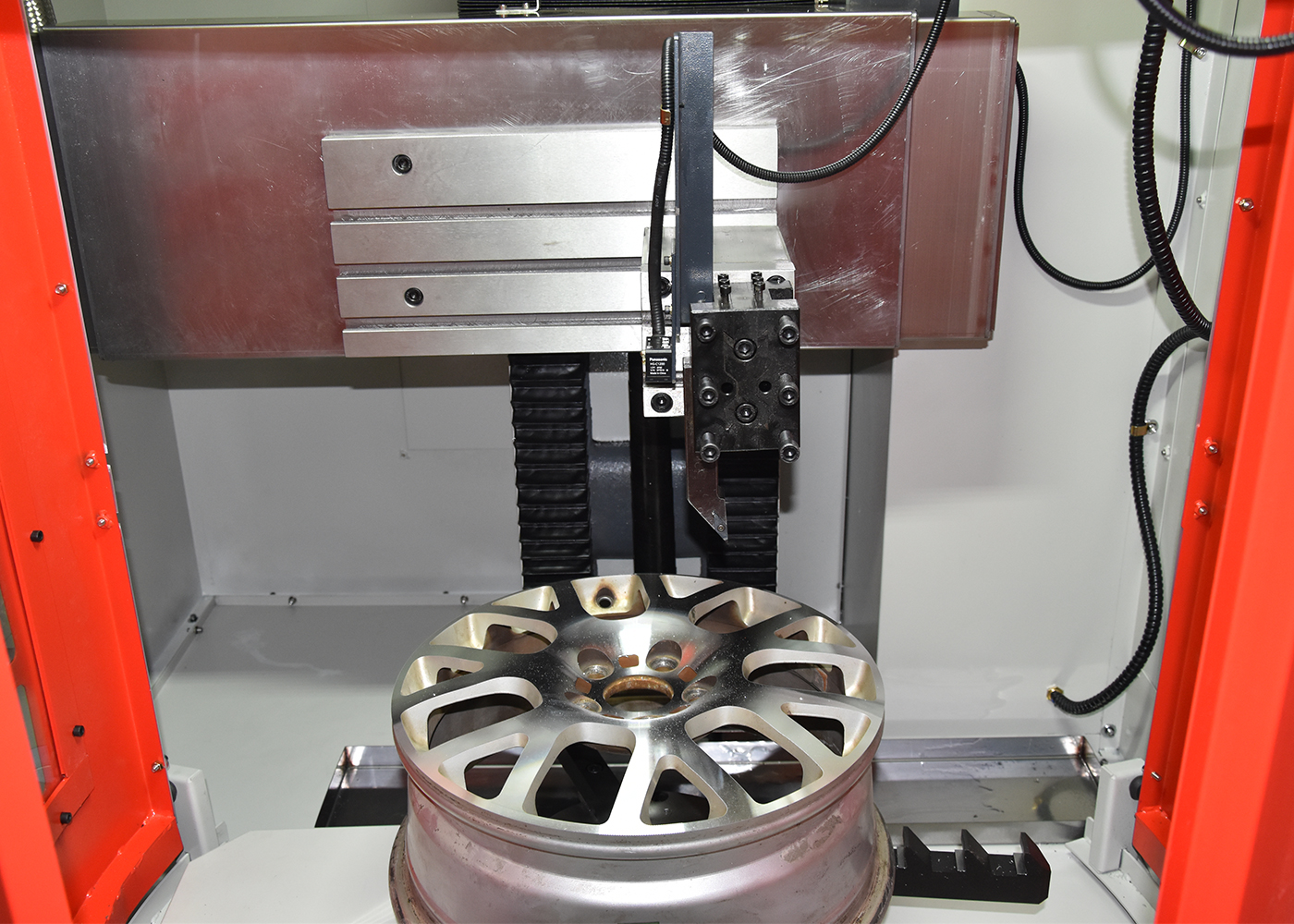

Since the wheel hub is made of aluminum alloy, there are high requirements for machining finish and precision. Therefore, we use linear guides for all three axes, which not only meet the needs for rapid movement but also improve the machining finish and precision of the wheel hub. Due to the large span, our ball screws are installed using a three-point support method, adding an extra layer of security in transmission.

What Makes the HAISHU Wheel Repair Lathe Unique for Wheel Repair with Tire?

The most notable highlight is HAISHU’s independently developed CNC system specifically for wheel repair. It not only supports laser detection and probe detection but also adds tooltip detection. With laser detection, the wheel hub surface can be measured in about 15 seconds. The system also supports fully automatic optimization or manual optimization. HAISHU pioneered the one-click tool setting function, allowing even those without a CNC background to easily operate the HAISHU machines. Fully mastering the CNC wheel repair machine takes approximately 30 minutes, providing the quick wheel repair service that customers need.

What Are the Specifications of the HAISHU Machine for Wheel Repair with Tire?

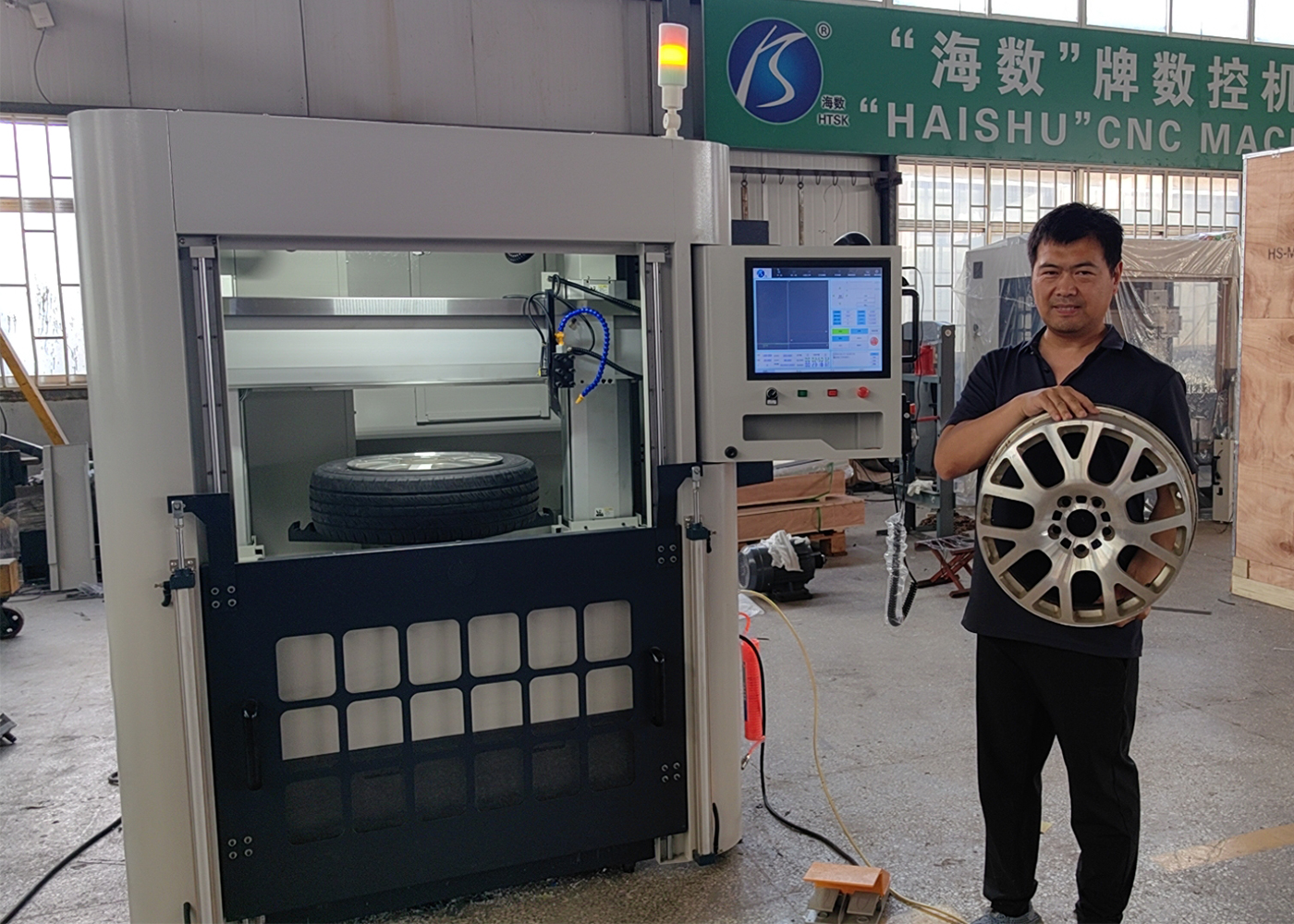

The model of this HAISHU machine is CKL35, with a maximum machining diameter of up to 35 inches. Users can directly clamp the machine without removing the tire. This model has gained a large customer base in the market and quickly captured the market in developed countries in Europe and America. HAISHU has also developed various models of wheel repair lathes to meet different needs. To provide on-site service, they developed a mobile wheel repair lathe CKL22Q. For agents who want their own branded wheel repair lathes, HAISHU offers professional ODM services, supporting custom voltages, logos, languages, and even integrating your company information into the CNC system. We look forward to business cooperation with you.

How Does HAISHU Ensure Quality in Wheel Repair with Tire?

HAISHU’s wheel repair lathe is designed to provide high precision and quality. The CNC system is tailored specifically for wheel repair, ensuring that each wheel is restored to its original condition with minimal effort. The machine’s ability to handle large turning diameters and its robust structure makes it ideal for repairing wheels with tires still attached. This not only saves time but also improves the overall efficiency of the repair process.

By investing in a HAISHU wheel repair machine, workshops can offer in-house wheel repair services, reducing the need for outsourcing and cutting costs. This not only speeds up service delivery but also boosts customer satisfaction. The wheel CNC machine is a must-have for any professional garage looking to enhance service quality and operational efficiency.

Conclusion

In conclusion, the process of wheel repair with tires has been revolutionized by HAISHU’s innovative wheel repair lathe. The vertical structure, high precision requirements, and unique CNC system make it an ideal solution for efficient and precise wheel hub repair. With models like CKL35 and CKL22Q, HAISHU provides versatile options to meet various needs, ensuring high-quality repairs while saving time and costs. Whether you are a repair shop or an agent looking for branded machines, HAISHU offers professional services and support to help you achieve your business goals.

With the right equipment, wheel repair with tire becomes a seamless and efficient process, enhancing the overall service quality and customer satisfaction. Invest in HAISHU’s wheel repair lathe today and experience the difference in precision, efficiency, and quality.