Unveiling the Top 1 Wheel Machining Center in the UK: HAISHU’s Pioneering Technology

In an era where the automotive and motorcycle industries are booming, the demand for high-quality wheels is escalating. Alloy aluminum wheels are at the forefront due to their dual benefits of ensuring vehicular rigidity and reducing overall weight. As economic development propels the need for these wheels, the efficiency of their production becomes crucial. This article delves into the sophisticated world of the top 1-wheel machining center in the UK, showcasing HAISHU’s innovation in wheel machining technology.

How Does the Top 1 Wheel Machining Center in the UK Ensure High Precision in Wheel Machining?

Traditional wheel machining centers typically involve the use of two slant bed CNC lathes and one vertical machining center. This conventional setup, while capable of producing wheels, often falls short in terms of precision and efficiency. The process of machining the A and B sides of wheels sequentially on different machines can lead to issues with concentricity. After the first machining phase, the wheel is transferred and re-clamped on another machine, which often compromises the precision of the final product.

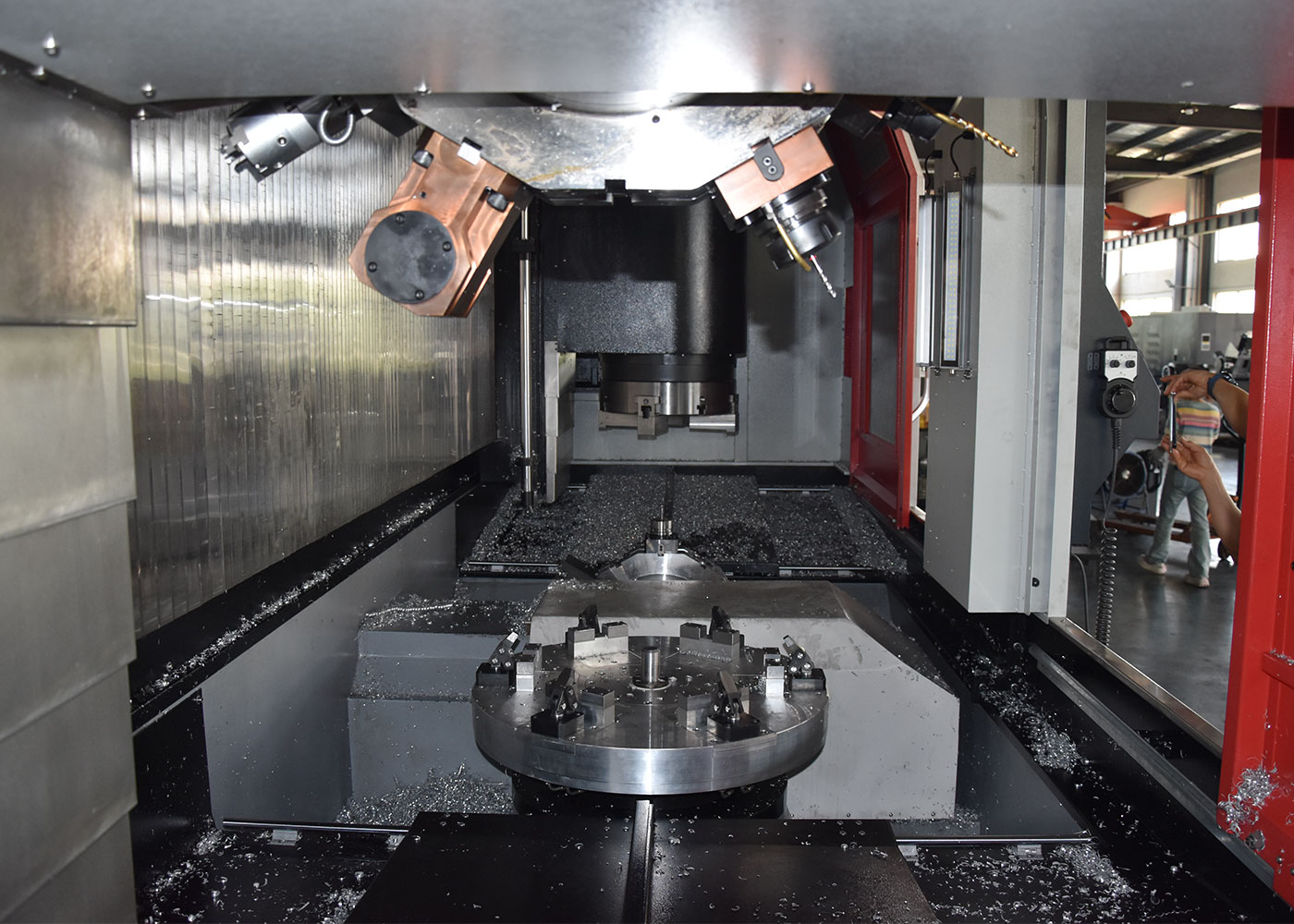

To counter these inefficiencies, HAISHU, the top 1 wheel machining center in the UK, has innovated with a vertical-inverted lathe-style wheel machining center. This advanced system features a unique setup where two spindles and two power turrets operate in conjunction, dramatically enhancing the concentricity and precision of the machining process.

What Innovations Does the Wheel Turning Center at the Top 1 Wheel Machining Center in the UK Offer?

HAISHU’s wheel turning center represents a significant leap in technology. Utilizing a vertical-inverted lathe configuration, it includes two spindles positioned one above the other. The upper spindle moves along a guide rail to align perfectly with the lower spindle, allowing for simultaneous and precise clamping of the wheel. This innovative clamping mechanism ensures that the wheel remains stable during the entire machining process, thus maintaining high precision in machining both sides of the wheel.

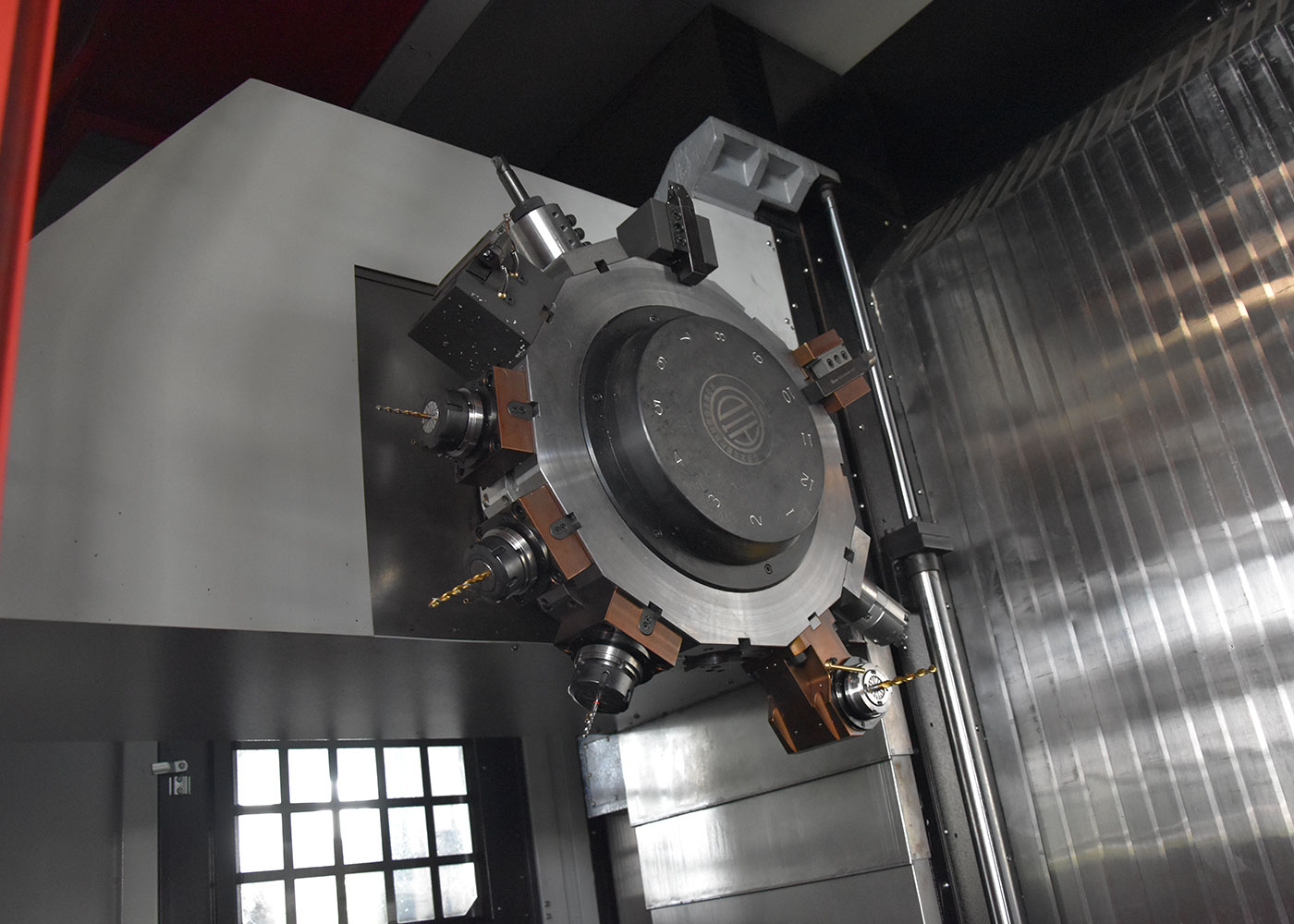

The center is equipped with a 650mm hydraulic chuck and a 12-station large power turret, each capable of holding powered tool holders. This setup not only facilitates efficient machining of the wheel rim and face but also uses anti-vibration tools to precisely machine inner holes.

How Does the Wheel CNC Machine at the Top 1 Wheel Machining Center in the UK Enhance Productivity?

The wheel CNC machine at HAISHU is designed for high efficiency and productivity. After the initial positioning and clamping, the first spindle engages with the wheel, and the 12-station power turret begins the machining process. Once the A-side is complete, the wheel is seamlessly transferred to the second spindle without needing repositioning, thus saving time and reducing the chance of errors.

The second spindle then takes over, machining the B-side of the wheel, including critical features such as PCD holes and valve holes. The power turret, equipped with drills and taps, ensures that these features are machined with high precision, keeping the mounting holes perfectly perpendicular.

How Does the Wheel Turning Lathe at the Top 1 Wheel Machining Center in the UK Improve Wheel Production?

HAISHU’s wheel turning lathe is integral to the wheel production process. It allows for the precise and efficient machining of both sides of the wheel in a single setup. The lathe’s configuration ensures that the wheel is securely clamped during the entire machining process, which is vital for achieving high-quality output.

After machining, the power turret on the B-side engages in a vertical movement to release the finished wheel using specially designed pneumatic clamps. This method not only protects the integrity of the freshly machined surfaces but also streamlines the transition of the wheel to the next phase of production, enhancing overall throughput.

What Future Technologies Are Being Developed by the Top 1 Wheel Machining Center in the UK?

Looking towards the future, HAISHU is not resting on its laurels. The top 1-wheel machining center in the UK is continuously exploring machining technology advancements to further enhance wheel production’s efficiency and precision. Innovations in automation and machine intelligence are key areas of focus, promising to revolutionize the way wheels are machined.

Why Do Customers Prefer the Top 1 Wheel Machining Center in the UK for Their Wheel Machining Needs?

Customers choose HAISHU, the top 1 wheel machining center in the UK, for several compelling reasons. The center’s commitment to innovation, precision, and efficiency ensures that each wheel is machined to the highest standards. The comprehensive approach, from initial design to final output, guarantees customer satisfaction and has led to long-term collaborations. Additionally, HAISHU’s ability to provide customized machining solutions further enhances its appeal in the competitive wheel machining market.

In conclusion, HAISHU represents the pinnacle of wheel machining technology in the UK, setting industry benchmarks with its innovative approaches and commitment to quality. As the automotive industry continues to evolve, HAISHU’s forward-thinking solutions ensure it remains at the forefront, driving advancements in wheel machining technology.