1. How Are CNC Wheels Near Me Repaired?

1.1 Understanding the Repair Process

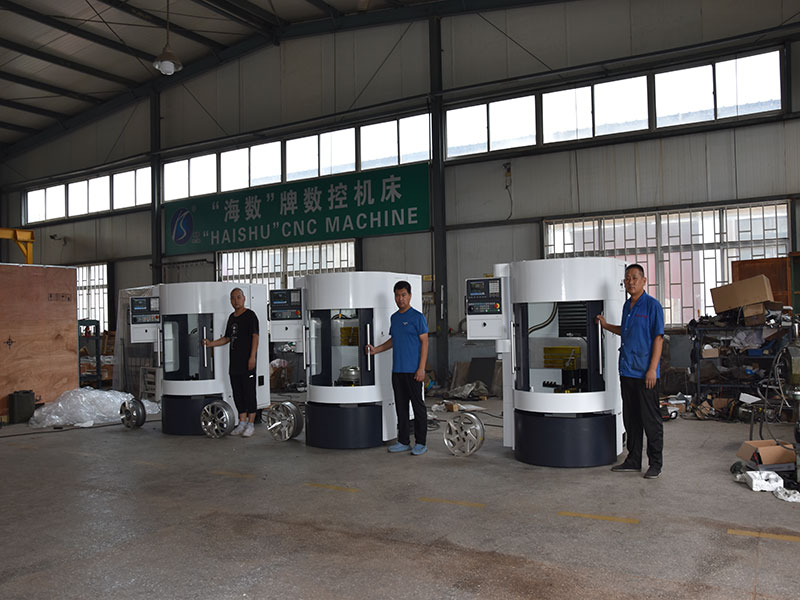

Customers often have concerns about how their car’s wheels are repaired, particularly regarding the type of wheel repair lathe(آلة إصلاح العجلات) or wheel repair machine(Radreparaturmaschine) utilized. A precision wheel CNC machine(Máy sửa chữa bánh xe) is typically employed for this purpose. This article will detail how these machines, specifically Tai’an Haishu’s diamond cutting wheel lathe, operate to restore deformed wheels effectively.

1.2 Initial Assessment of the Wheel

Before any repairs begin, the first step is to determine if the removed car wheel has been deformed. If the wheel is intact, it will undergo a thorough cleaning using a specialized cleaning machine. After cleaning, the entire wheel is painted with spray painting equipment. This not only enhances the aesthetic appeal but also protects the wheel from further damage. Once painted, the wheel is placed in an oven for drying to ensure a solid finish.

2. What Clamping Solutions Are Available for CNC Wheels Near Me?

2.1 Innovative Clamping Designs

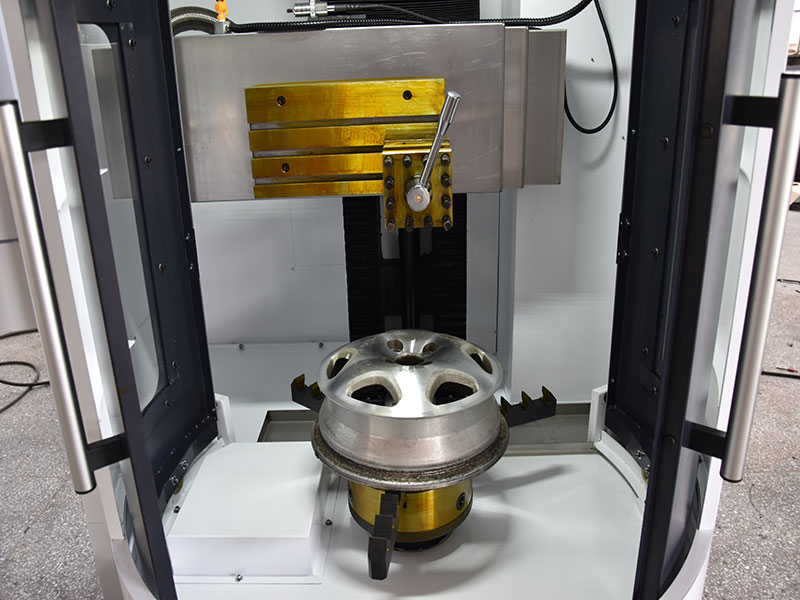

To facilitate the clamping of wheels, Tai’an Haishu has developed extended clamps equipped with barbed teeth. This design improves the speed and security of the clamping process. The current design is the result of the fourth generation of product upgrades, which have included three-jaw, four-jaw, and six-jaw options. However, 98% of wheels typically require only a three-jaw chuck, as it provides the most secure hold.

2.2 Custom Multi-Jaw Structures

Tai’an Haishu also offers custom multi-jaw structures for slightly deformed wheels that may not fit snugly in standard chucks. These specialized clamps ensure that even irregularly shaped wheels can be securely fixed, allowing for precise machining without slippage.

3. How Are CNC Wheels Near Me Detected?

3.1 Probing Methods for Accurate Detection

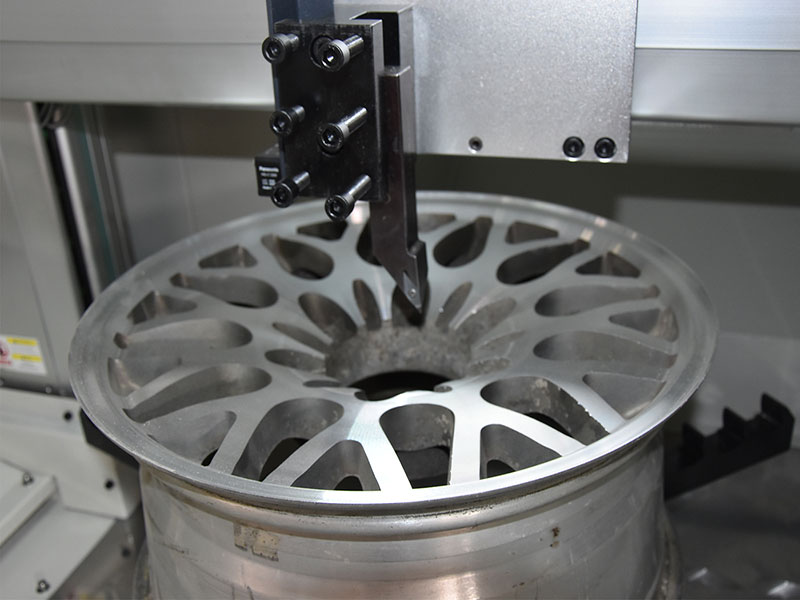

After clamping the wheel, one of three probing methods must be used for detection. These methods include:

- Laser Probing: The quickest and most convenient option, taking only 15 seconds to complete surface detection.

- Probe Probing: A slower method, requiring approximately 6-10 minutes, ideal for deep curved surfaces.

- Tip Probing: The slowest but most precise method, which involves direct contact with the wheel surface, ensuring accurate measurements.

All probing methods feature user-friendly button settings, making them easy to operate, even for those without extensive training.

3.2 Optimizing Detected Curves

Once the detection is complete, the detected curve must be optimized for profiling machining. Tai’an Haishu offers two optimization methods: automatic and manual.

- Automatic Optimization: Best for smoother wheel surfaces, allowing for one-click output of the machining program.

- Manual Optimization: Ideal for wheels with significant curve variations, requiring the selection of points from the detected curve to ensure they align closely.

This manual approach doesn’t require external curve adjustments, saving time and making operations more efficient.

4. How Does CNC Programming Work for Wheels Near Me?

4.1 Simplifying CNC Programming

After the curve optimization, the CNC program can be directly outputted. This significantly reduces the skill requirements for machinists. Even individuals without a foundational knowledge of CNC operations can produce programs comparable to those created by experienced professionals. This user-friendly design lowers labor costs and enables business owners to operate the machines themselves, enhancing their competitiveness in the wheel repair market.

4.2 One-Click Tool Setting Function

An essential feature in this process is the one-click tool setting function. The machining result depends heavily on the tool setting position. Accurate tool settings ensure the desired machining effect is achieved. Tai’an Haishu’s design allows for easy setting of X and Z axis coordinates, eliminating complex procedures typically associated with tool setting.

5. What Are the Steps for Machining CNC Wheels Near Me?

5.1 Initial Machining Adjustments

Once the tool is set, CNC machining and repair can commence. Initially, minimal cutting should be performed to observe the machining surface effect. Any unmachined areas can be adjusted in real time by modifying coordinates. This iterative process ensures that the repair is perfected through repeated machining cycles, typically ranging from three to five.

5.2 Final Touches and Balancing

After achieving the desired wire drawing effect, the wheel must be cleaned and sprayed with clear paint before being dried in an oven. Once the paint has dried, tires are mounted on the repaired wheels, followed by balancing. This comprehensive process ensures that the wheel is not only aesthetically pleasing but also safe and functional for use.

6. Where to Find Reliable CNC Wheel Repair Services Near Me?

6.1 Professional Services and Equipment

For those seeking reliable CNC wheel repair services, it’s important to connect with experienced providers who utilize advanced wheel repair machines and aluminum wheel CNC lathes(máquina de reparación de ruedas). Tai’an Haishu specializes in offering high-quality CNC alloy wheel repair solutions.

6.2 Contacting Experts for Assistance

If you require further details or information about wheel repair equipment and services, don’t hesitate to reach out promptly for professional assistance. Engaging with experts ensures you receive the best solutions tailored to your specific needs.

7. Conclusion: The Importance of Quality Wheel Repair

In conclusion, understanding the process of repairing CNC wheels can significantly enhance your knowledge and confidence when seeking wheel repair services. By utilizing advanced technologies like wheel CNC machines and precision wheel repair lathes, you can ensure that your car’s wheels are restored to their optimal condition, enhancing safety and performance. For any inquiries or to explore our range of services, please contact us today.