What Kind of Combination Does the Wheel Rim Repair Lathe UK Have?

With economic development, the demand for transportation tools has been increasing, and the number of cars owned has been rising. Consequently, the market for car beauty and maintenance has also developed. So, what should the correct wheel rim repair lathe UK be like? HAISHU will provide a detailed explanation through this article, allowing you to understand the modern form and combination of wheel rim repair lathes in the UK.

What Are the Common Issues Addressed by a Wheel Rim Repair Lathe UK?

Car wheel rims generally face various issues such as scratches, deformation, cracks, or missing parts. For these different types of wheel rims, multiple combination methods are usually adopted. These include wheel rim straightening machines, wheel rim repair lathes, wheel rim polishing machines, wheel rim cleaning machines, wheel rim painting, and wheel rim ovens. Today’s article will mainly explain the combination of wheel rim straightening machines and wheel rim repair lathes, specifically focusing on the UK market.

How Does a Wheel Rim Straightening Machine Work in Combination with a Wheel Rim Repair Lathe UK?

Generally, if the wheel rim is deformed or cracked, it first needs to be corrected on a wheel rim straightening machine. First, use a dial indicator to determine if the wheel rim is deformed. If deformation is found, mark it with a marker. Then, use a heat gun to heat the area, and then use an automatic hydraulic top with a special top tool to reshape the deformed area. If the wheel rim has cracks or missing parts, professional aluminum welding tools are needed for welding. After that, use a cutting tool to machine the welded area before reshaping the wheel rim. By repeating these actions and then using a dial indicator to check the wheel rim for runout, the next step of turning the wheel rim can be carried out. This process usually takes about 30 minutes.

What Are the Different Types of Wheel Rim Repair Lathe UK?

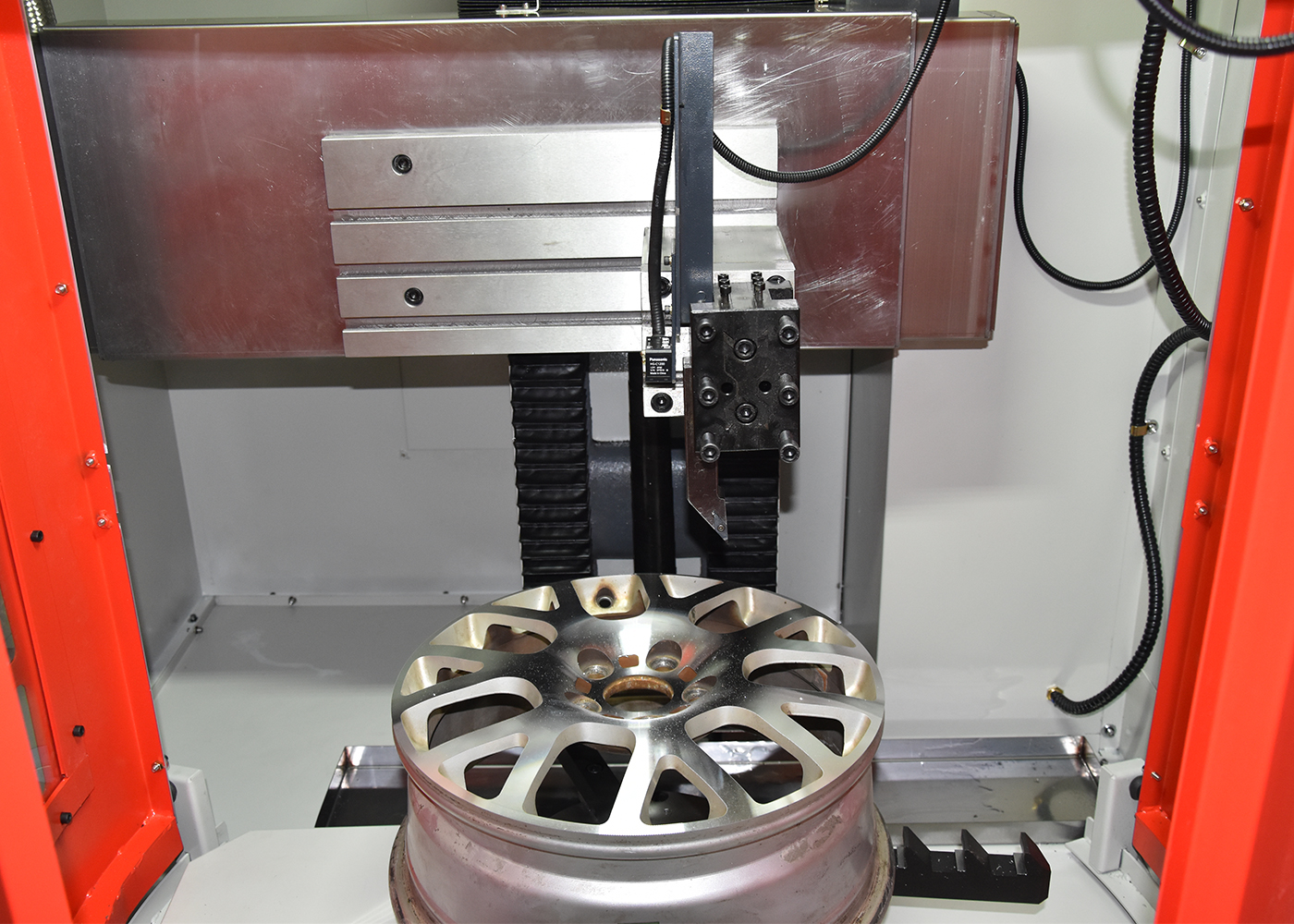

After confirming that the runout has been repaired, the wheel rim needs to be clamped onto a wheel rim repair lathe. Wheel rim repair lathes come in various forms, such as horizontal wheel rim repair lathes and vertical wheel rim repair lathes. This wheel rim repair machine is also the most important machine in the entire wheel rim repair and beauty process. First, if the wheel rim is relatively large, it needs to be clamped in a parallel direction on a special wheel rim fixture. Then, use HAISHU’s special wheel rim repair system equipped with a laser probe for quick laser detection, which takes only about 15-20 seconds. The wheel rim curve will then automatically display on the system, eliminating the need for the previous method of importing the curve into a USB drive and optimizing it externally, which was time-consuming. The system can directly perform automatic optimization and can also output CNC machining programs with one click, which is very user-friendly for those with no repair experience. Finally, use the specially designed one-click tool setting function to save the operator from complex tool setting steps. Then, the surface repair of the wheel rim can be carried out. Additionally, HAISHU has designed a safety door feature that automatically stops machining if the protective door is opened during processing, protecting the operator.

How Do Wheel Repair Lathe UK and Other Machines Enhance the Repair Process?

In the wheel rim repair industry, especially in the UK, it is crucial to have a combination of different machines to ensure comprehensive repair and maintenance. For instance, a wheel repair lathe is essential for precise machining of the wheel surface, while a wheel repair machine can handle various other aspects of the repair process, such as cleaning and polishing. The integration of a wheel CNC machine allows for automated and highly accurate repairs, reducing human error and ensuring consistency. An alloy wheel lathe is particularly important for handling modern alloy wheels, which require specialized equipment due to their unique properties. Similarly, a CNC wheel lathe provides detailed and precise repair capabilities, making it an invaluable addition to any wheel repair shop.

What Are the Benefits of Using a HAISHU Wheel Rim Repair Lathe UK?

HAISHU’s wheel rim repair lathes are designed with advanced technology and user-friendly features, making them ideal for both experienced technicians and those new to wheel repair. The key benefits include:

- Precision and Accuracy: With laser probes and CNC capabilities, HAISHU’s wheel rim repair lathe ensures that every repair is precise, enhancing the overall quality of the wheel.

- Efficiency: The automation features reduce the time required for each repair, allowing for quicker turnaround times.

- Safety: Features like the safety door ensure that the machine stops automatically if the door is opened, protecting the operator from potential hazards.

- User-Friendly Interface: The system is designed to be intuitive, with functions like one-click tool setting making it accessible even for those with limited experience.

- Versatility: Capable of handling various types of wheels and repairs, HAISHU’s equipment is versatile and adaptable to different needs.

How to Choose the Right Wheel Rim Repair Lathe UK?

When selecting the right wheel rim repair lathe in the UK, it is essential to consider several factors to ensure you get the best equipment for your needs. Here are some tips:

- Assess Your Needs: Determine the types of wheels you frequently repair and choose a lathe that can handle those specific requirements.

- Look for Versatility: A versatile machine that can perform multiple functions, such as cutting, polishing, and straightening, will be more valuable in the long run.

- Consider Automation: Automated features like CNC programming and laser detection can significantly enhance efficiency and accuracy.

- Check for Safety Features: Ensure the machine has adequate safety features to protect operators during use.

- Evaluate Support and Service: Choose a manufacturer like HAISHU that offers comprehensive support and service, including training and maintenance.

Conclusion

In conclusion, the wheel rim repair lathe UK market is evolving with advanced technologies and comprehensive solutions. HAISHU provides a range of equipment, including wheel repair lathes, wheel repair machines, wheel CNC machines, alloy wheel lathes, and CNC wheel lathes, designed to meet the diverse needs of the automotive repair industry. By understanding the different configurations and benefits of these machines, you can ensure that your repair shop is equipped with the best tools to deliver high-quality repairs and exceptional customer service. For more information and updates on wheel rim repair, continue to follow HAISHU’s articles and website. We are also seeking more partners and agents to expand our reach and provide top-notch solutions to the automotive repair industry.