1. Experience Cutting-edge Technology For Repairing Diamond-cut Wheels.

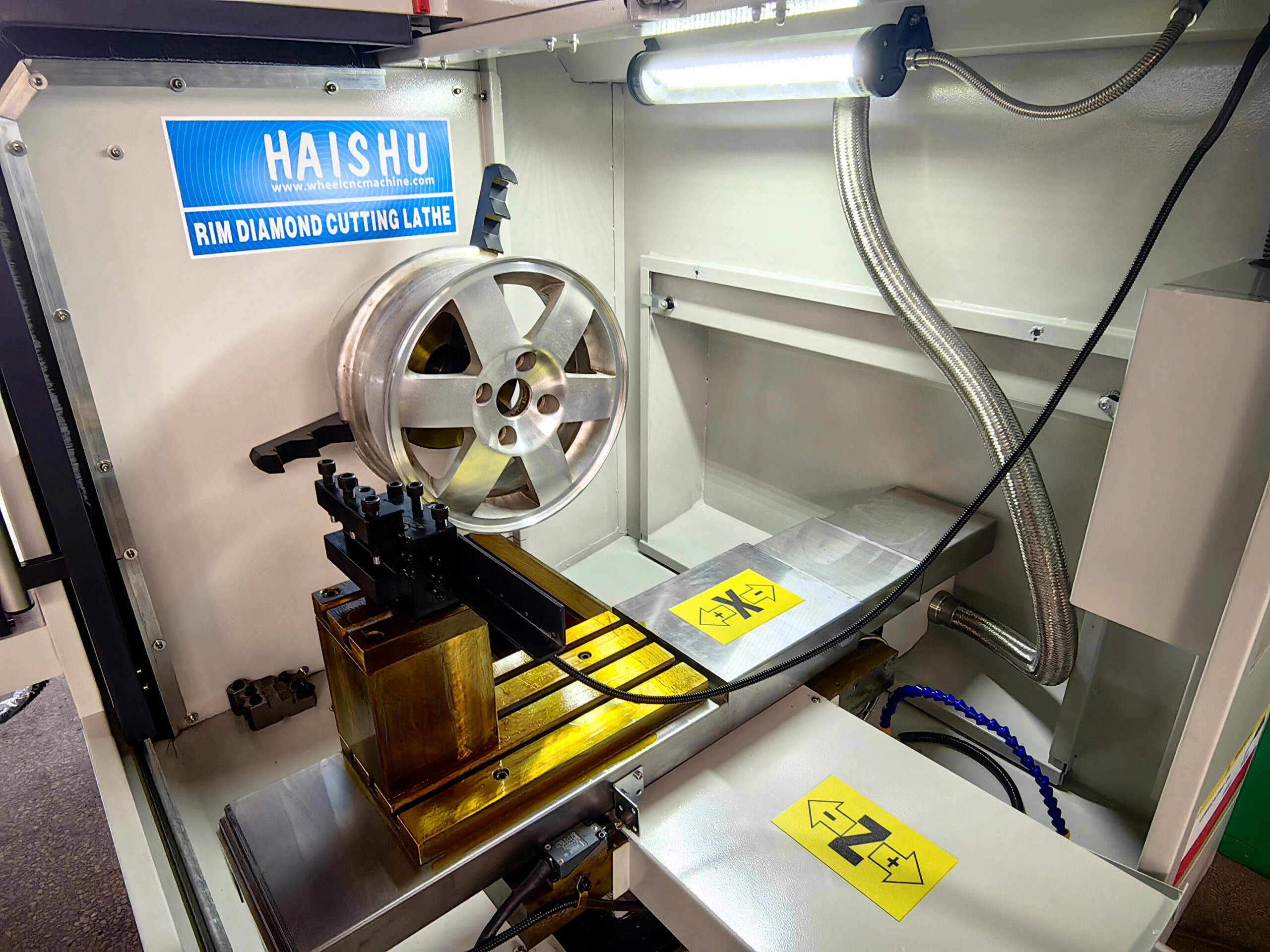

Our fully automated Alloy Wheel Repair Machine offers unparalleled quality and efficiency, ensuring the highest quality finish and the fastest turnaround time in the industry. Equipped with advanced technology, this wheel cutting repair machine is specifically designed for precision repairs on alloy wheels.

The alloy wheel diamond cutting machine utilizes cutting-edge techniques to make precise micromillimeter adjustments to damaged wheels. It employs diamond-cutting tools to remove imperfections and restore the wheels to their original pristine condition. This process not only enhances the visual appeal of the wheels but also ensures their structural integrity remains intact.

With its automated functionality, the wheel CNC machine streamlines the repair process, minimizing human error and maximizing productivity. It is capable of handling various types of alloy wheels and can effectively address a wide range of damages, including scratches, dents, and curb rash.

By utilizing this advanced machine, wheel repair professionals can achieve exceptional results with unparalleled precision and accuracy. The quick turnaround time allows for faster completion of repairs, reducing downtime for customers and enhancing overall customer satisfaction.

Whether you are in the automotive industry or a wheel repair specialist, our alloy wheel repair machine is a valuable asset for your business. It not only delivers superior quality finishes but also optimizes operational efficiency, helping you meet customer demands and stay ahead in a competitive market.

Invest in our alloy wheel repair lathe and experience the benefits of high-quality repairs, efficient turnaround times, and satisfied customers.

2. What are wheel cutting repair machine wheels?

Wheel cutting repair machines are specifically designed to cater to the needs of diamond cut wheels. Diamond cut wheels are alloy wheels that undergo a precise machining process on a lathe, where a portion or the entire painted surface of the wheel is carefully removed, leaving behind a lustrous alloy finish. During this process, a thin layer of the actual alloy is shaved off to achieve the desired appearance. To protect the exposed alloy surface from corrosion, a protective lacquer is applied.

The popularity of alloy wheels in new car models has been steadily increasing, with manufacturers offering them as a standard choice for buyers. Consequently, there is now a vast array of designs available in the market to cater to different preferences. As the demand for alloy wheels continues to soar, so does the need for diamond cut wheel repairs. Car owners are becoming increasingly invested in maintaining the pristine appearance of their wheels, and diamond cut repairs emerge as the ideal solution to achieve this goal.

When it comes to repairing diamond cut wheels, wheel cutting repair machines play a crucial role. These machines are equipped with advanced technology and specialized tools to effectively restore and refurbish diamond cut wheels. They offer precise control over the machining process, ensuring that the right amount of alloy is removed to achieve a flawless finish. With their capabilities, wheel cutting repair machines enable technicians to seamlessly address various issues such as scratches, scuffs, and imperfections on diamond cut wheels.

Moreover, the integration of protective lacquer is a critical step in the repair process. It not only enhances the visual appeal of the wheels but also safeguards them from damage caused by environmental factors, such as corrosion and oxidation. The application of a high-quality lacquer ensures long-lasting protection, allowing the wheels to maintain their shine and overall aesthetic appeal for an extended period.

In summary, the rising trend of alloy wheels in the automotive industry has led to an increased demand for diamond cut wheel repairs. Wheel cutting repair machines play a vital role in this process, utilizing advanced technology and precision tools to restore the wheels to their original glory. By opting for diamond cut repairs, car owners can retain the new and impeccable look of their wheels, ensuring a visually appealing and well-maintained vehicle.

3. Simple Intuitive Software

Our Alloy Wheel Repair Machine features user-friendly and intuitive software developed in Denmark. This tailor-made software provides a seamless and straightforward repair experience for alloy wheels. With a touchscreen interface, the software offers clear visualizations of each step of the repair procedure, ensuring ease of use.

Unlike other rim repair machines that are often converted CNC lathes, our machine is purpose-built for alloy repair. This means that workshops no longer need to invest in larger installations with complex user software. Our software is specifically designed to simplify the repair process and enhance efficiency.

With our simple and intuitive software, technicians can effortlessly navigate through the repair procedure, saving time and effort. The user-friendly interface ensures that even those with minimal technical expertise can operate the machine effectively.

By incorporating this advanced software into our Alloy Wheel Repair Machine, we provide a seamless and efficient solution for repairing alloy wheels. Experience the convenience and effectiveness of our tailor-made software, designed to optimize your alloy repair operations.

4. What are the other advantages of the software for the wheel cutting repair machine?

4.1 Our advanced alloy wheel repair machine offers several innovative features that enhance efficiency and precision. With the ability to make up to 3 cuts without the operator’s presence, the machine allows for multitasking, enabling the operator to work on other tasks while the rim is being cut. This feature increases productivity and saves valuable time.

4.2 The auto position feature is another remarkable addition to our alloy wheel repair machine. By calibrating the machine to measure the distance from the laser to the cutting tool, it ensures faster and more accurate results with every repair. This precise calibration eliminates guesswork, delivering consistent and high-quality outcomes.

4.3 To facilitate monitoring and maintenance, our machine is equipped with a diagnostics screen. This screen provides a comprehensive overview of the machine, allowing operators to check the functionality of sensors, laser, buttons, and software. By ensuring that all components are working correctly, the diagnostics screen enables better support and troubleshooting, minimizing downtime.

4.4 These features not only streamline the repair process but also contribute to improved overall performance and customer satisfaction. The ability to multitask and the precision offered by the auto position feature ensure efficient and accurate repairs, while the diagnostics screen aids in identifying and resolving any potential issues promptly.

4.5 Investing in our alloy wheel repair machine with these cutting-edge features means investing in increased productivity, faster turnaround times, and enhanced customer service. Experience the benefits of advanced technology and optimize your alloy wheel repair operations with our state-of-the-art machine.