Wheel Refurbishment: A Cost-Effective Alternative to New Alloys

Have you ever wondered if there’s a way to restore your car’s alloy wheels to their former glory without breaking the bank? Wheel refurbishment might just be the solution you’re looking for. Not only is it more cost-effective than purchasing new wheels, but it can also give your vehicle a fresh, appealing look and maintain its value.

What Is Wheel Refurbishment?

Wheel refurbishment is the process of repairing and restoring alloy wheels to a like-new condition. This service is essential for fixing various forms of damage, such as scratches, scuffs, and corrosion that can occur through everyday driving, particularly from unintended contact with curbs.

Why Should You Consider Wheel Refurbishment?

Can Alloy Wheel Refurbishment Maintain Your Car’s Value?

Yes, refurbishing your alloy wheels can prevent further damage and maintain or even increase your vehicle’s resale value. It’s not just about aesthetics; it’s also about preserving the structural integrity of your wheels.

How Does Wheel Refurbishment Enhance Your Car’s Appearance?

Refurbishing your wheels can significantly improve your car’s curb appeal. Restored wheels look brand new, enhancing the overall appearance of your vehicle.

The Wheel Refurbishment Process

Step 1: Wheel Assessment and Damage Evaluation

How do technicians assess damage on alloy wheels?

A trained technician will begin by removing the wheel from the car and the tire from the wheel. They will inspect the alloy to determine the extent of the damage and the necessary repairs.

Step 2: Stripping and Sanding

What happens during the stripping and sanding phase of wheel refurbishment?

The existing finish is stripped away to reveal the bare metal. Small scuffs and scratches are sanded out, while larger damaged areas may require a filler to be applied and then sanded until smooth.

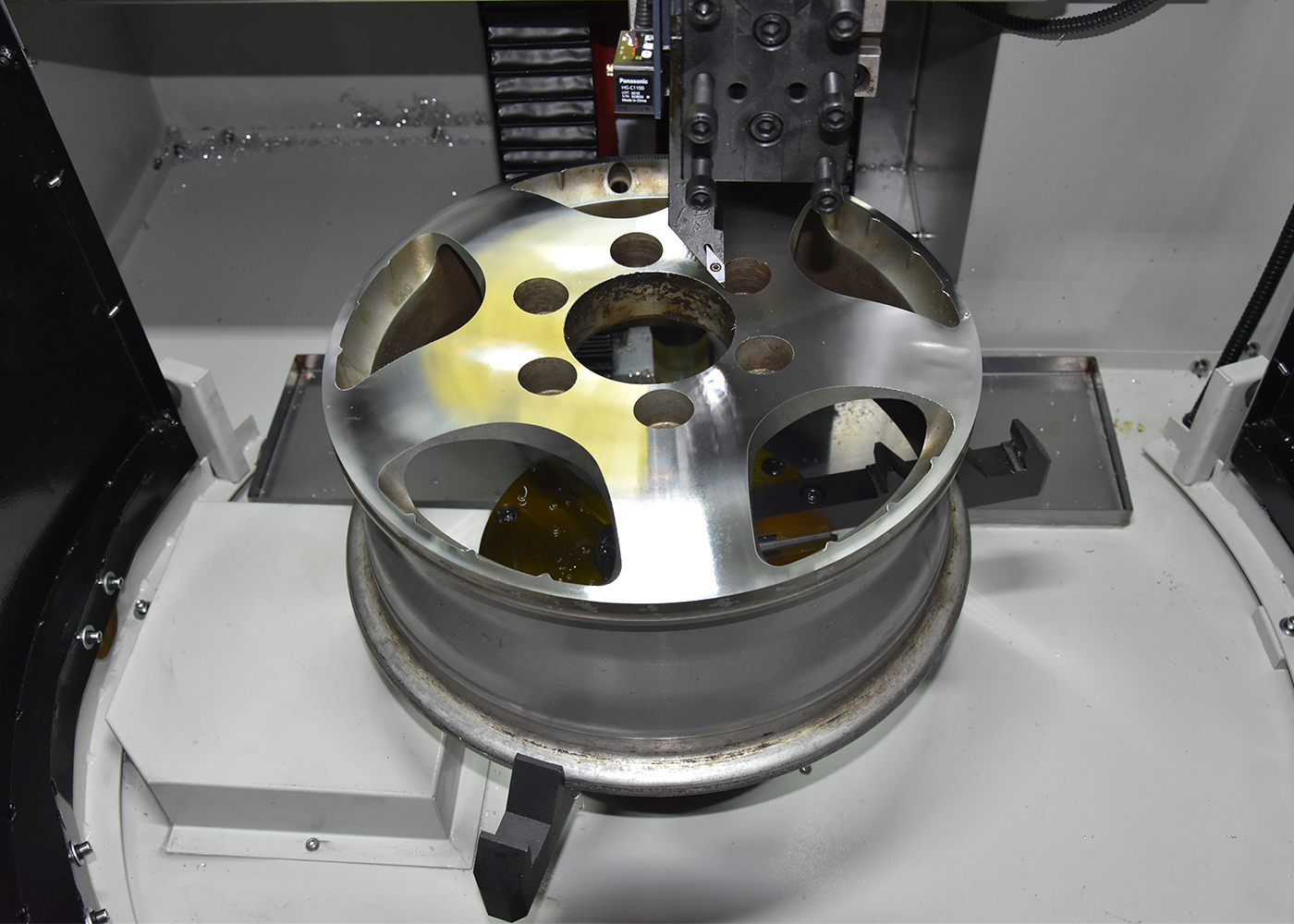

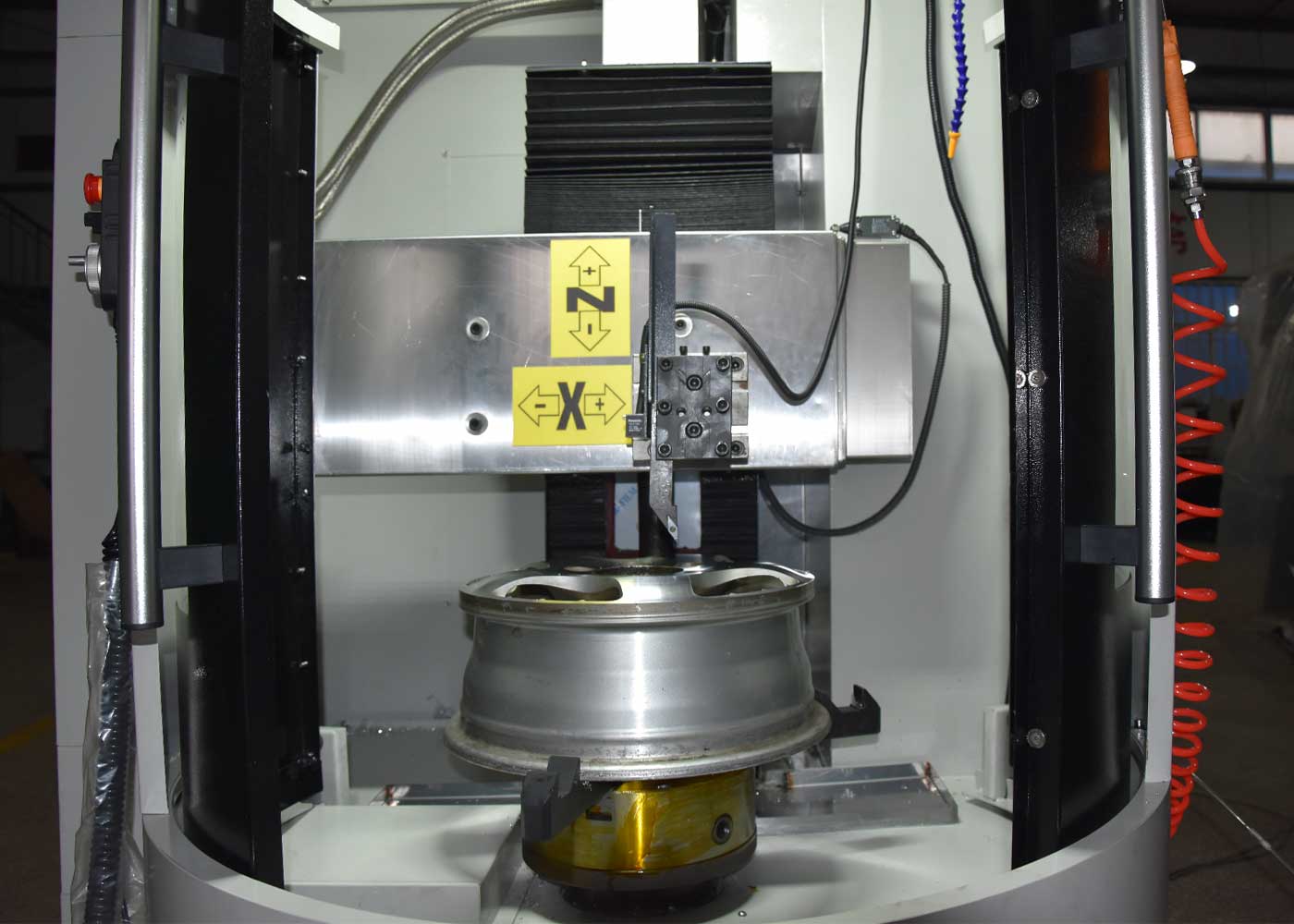

Step 3: Damage Repair with Precision Tools

How is more severe damage repaired in the refurbishment process?

For more extensive damage, a wheel repair lathe or wheel CNC machine is used. These precision tools can remove just the right amount of metal and reshape the wheel without affecting its original strength.

Step 4: Repainting and Finishing

What steps are involved in repainting refurbished wheels?

Once the wheel is repaired, it’s cleaned, primed, and painted with a color that matches the original finish. A protective lacquer coat is then applied, followed by curing and polishing for a shiny, protective finish.

Advanced Wheel Repair Equipment

What Role Does a Wheel Repair Lathe Play in Refurbishment?

A wheel repair lathe is crucial for accurately cutting and reshaping the wheel. It ensures that the wheel is perfectly round and balanced, which is essential for a smooth ride.

How Does a Wheel Repair Machine Enhance the Refurbishment Process?

A wheel repair machine can include various functions, from straightening bent wheels to polishing and buffing out minor imperfections, ensuring a comprehensive refurbishment.

What Is the Advantage of a Wheel CNC Machine?

For more complex repairs, a wheel CNC machine offers unparalleled precision. It can restore wheels with intricate designs and ensure that the repairs are undetectable and durable.

Final Thoughts on Wheel Refurbishment

Is Wheel Refurbishment Worth the Investment?

Absolutely. Investing in wheel refurbishment can save you money in the long run and keep your car looking its best. It’s a smart choice for any car owner who values their vehicle’s appearance and performance.

By choosing a professional wheel refurbishment service, you can ensure your wheels are restored to their original condition, enhancing both the look and value of your car. Remember to ask if they have state-of-the-art equipment like a wheel repair lathe and wheel CNC machine to guarantee the best results.