Wheel Refurbishment CNC Machine CK6160W is the newly designed wheel repair lathe by Taian Haishu Machinery Company. This wheel repair lathe CK6160W adopts a single-spindle and single-tool frame structure, which has high production efficiency and processing precision. The wheel repair lathe CK6160W is suitable for wheel processing with a large batch size, high processing precision, and good dimensional consistency. This Alloy Wheel Surface Repair lathe has a fully enclosed sheet metal construction. The wheel CNC lathe CK6160W has a good protective effect and a beautiful appearance. At the same time, this Alloy Wheel Surface Repair lathe can process the car wheel up to 22 inches. Various precision indicators meet or exceed The level of similar foreign machine tools that are the first choice for the automotive industry to process wheel parts.

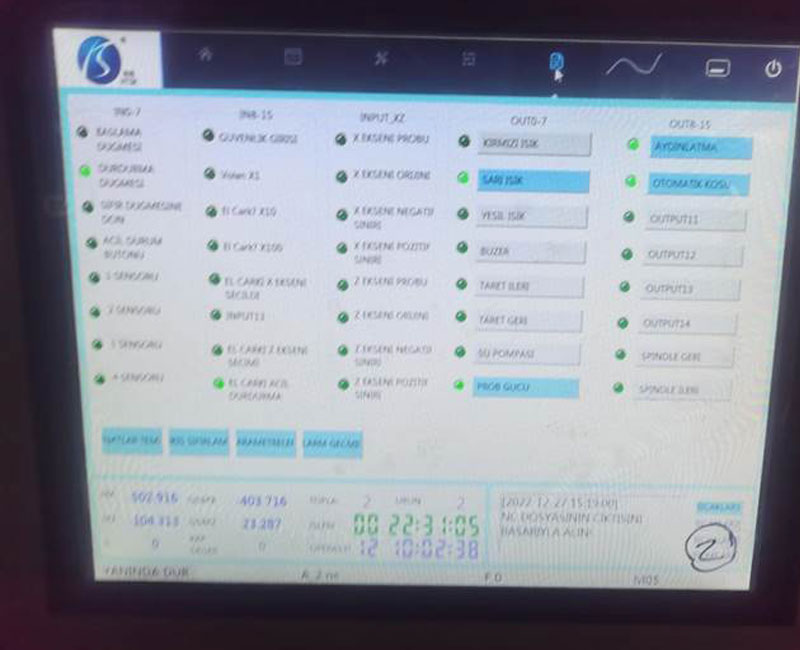

This Turkey customer requested an automatic wheel CNC lathe. He had confirmed the model number Wheel Refurbishment CNC Machine CK6160W from our website. After checking the max wheel size, they chose the Alloy Wheel Surface Repair lathe CK6160W. After they saw the operation video of the Alloy Wheel Surface Repair lathe CK6160W, they were very satisfied and wanted to order several sets. But they wanted to change his own appearance color and language and sent us the color card. After confirming we can customize the color and language for them for free, he arranged a deposit soon.

After the Wheel Refurbishment CNC Machine CK6160W was completed, we sent them the Alloy Wheel Repair lathe test video and detailed pictures. He was very satisfied and expressed they will order more soon.

Wheel Refurbishment CNC Machine CK6160W Specifications

| Item | Unit | Specifications |

| Max Wheel Diameter | inch | 22″ |

| X-axis maximum stroke | mm | 320 |

| Main motor power | kw | 3 |

| Rial Width | mm | 260 |

| Max. workpiece length | mm | 500 |

| Wheel measuring direction | X,Z | |

| Measuring Tool | Laser or probe (optional) | |

| Measurement method | Point measurement and quick scan | |

| Program optimization | Manual and automatic | |

| Number of wheel processing programs | rows | 100000 |

| CNC System | “HAISHU” special system (touch screen operation, 17 “screen LCD display).

Universal CNC system (key operation, 10.4 “screen LCD display) (optional) |

|

| Wheel processing | Surface, rim | |

| Mchining accuracy | um | IT6~IT7 |

| Main drive form | Frequency control, servo drive (optional) | |

| Spindle speed | Factory setting 150~2800 | |

| Fast-moving feed | mm/min | X :5000 Z :8000 |

| Repeat accuracy | mm | X :0.01 Z :0.015 |

| Turret form | Fixed turret,Electric turret (optional) | |

| Section of turning tool | mm | 25×25 |

| Machine size(L×W×H) | mm | 1900×1400×1750 |

| Net weight | kg | 1300 |

Wheel Refurbishment CNC Machine CK6160W Features

- The Wheel Machine has the advantages of a simple structure, low cost, and a high performance-price ratio.

- The Diamond Cut Wheel lathe can be selected by laser scanning or probe click measurement.

- Wheel data is automatically stored, machining program is arbitrarily called out.

- Software independent development, the program automatically optimize

- Wheel processing is automatically precise and fast

- The wheel CNC lathe is operated by a touch screen, and the system interface supports many languages.

- X / Z axis measurement, wheel surface, and circumferential machining.

- The wheel repair Machine is equipped with an automatic lubrication system.

- The Wheel CNC Machine with diamond tool turning makes the wheel surface more smooth.

- The Alloy Wheel Surface Repair lathe machine has the teaching function of the computer.

- The Alloy Wheel Surface Repair lathe can be customized according to customer requirements.

About Haishu Machinery

Haishu Machinery is a modern professional company specializing in R&D, manufacturing, sales, technical training and import trade of automotive Wheel Refurbishment CNC machines. Since its inception, our company has established long-term strategic partnerships with a number of world-renowned American automotive professional maintenance companies. We have introduced and digested world-leading automotive aluminum alloy wheel repair technologies and processes, filling a number of Chinese automobile wheels. To repair the gaps in the project, the company is determined to explore the professional Alloy Wheel Surface Repair lathe machine in China and lead the wheel repair trend. It is a truly green energy-saving and environmental protection enterprise that repairs old wheels and turns waste into treasure.