HAISHU CNC Vertical Lathes: Pinnacle of Wheel Repair Technology

The Fusion of Precision and Efficiency in Wheel Restoration

What sets the HAISHU CKL22Q and CKL35 apart in the industry?

HAISHU’s CKL22Q and CKL35 models redefine the standards for wheel repair CNC vertical lathe. These machines encapsulate the perfect balance between precision engineering and operational efficiency, essential for high-quality alloy wheel repair.

Advanced Interface for Streamlined Wheel Repair Operations

How does the HAISHU touchscreen CNC system enhance the repair process?

The HAISHU series boasts a state-of-the-art LCD touchscreen CNC system specifically optimized for the wheel repair lathe models CKL22Q and CKL35. This cutting-edge user interface simplifies complex tasks, allowing even novice operators to attain precise control during wheel repair machine operations, reducing the learning curve significantly.

Versatility with Flexible System Options

What does the SYNTEC 6TA CNC system offer to wheel repair professionals?

For workshops demanding greater adaptability, the optional SYNTEC 6TA CNC system extends the capabilities of the wheel CNC machine. While it differs from HAISHU’s custom system, it still offers a solid foundation for a wide array of CNC wheel repair tasks, ensuring that the CKL22Q and CKL35 models remain versatile and future-proof.

Engineering Excellence in Wheel CNC Lathe Design

Accurate Damage Detection and Repair

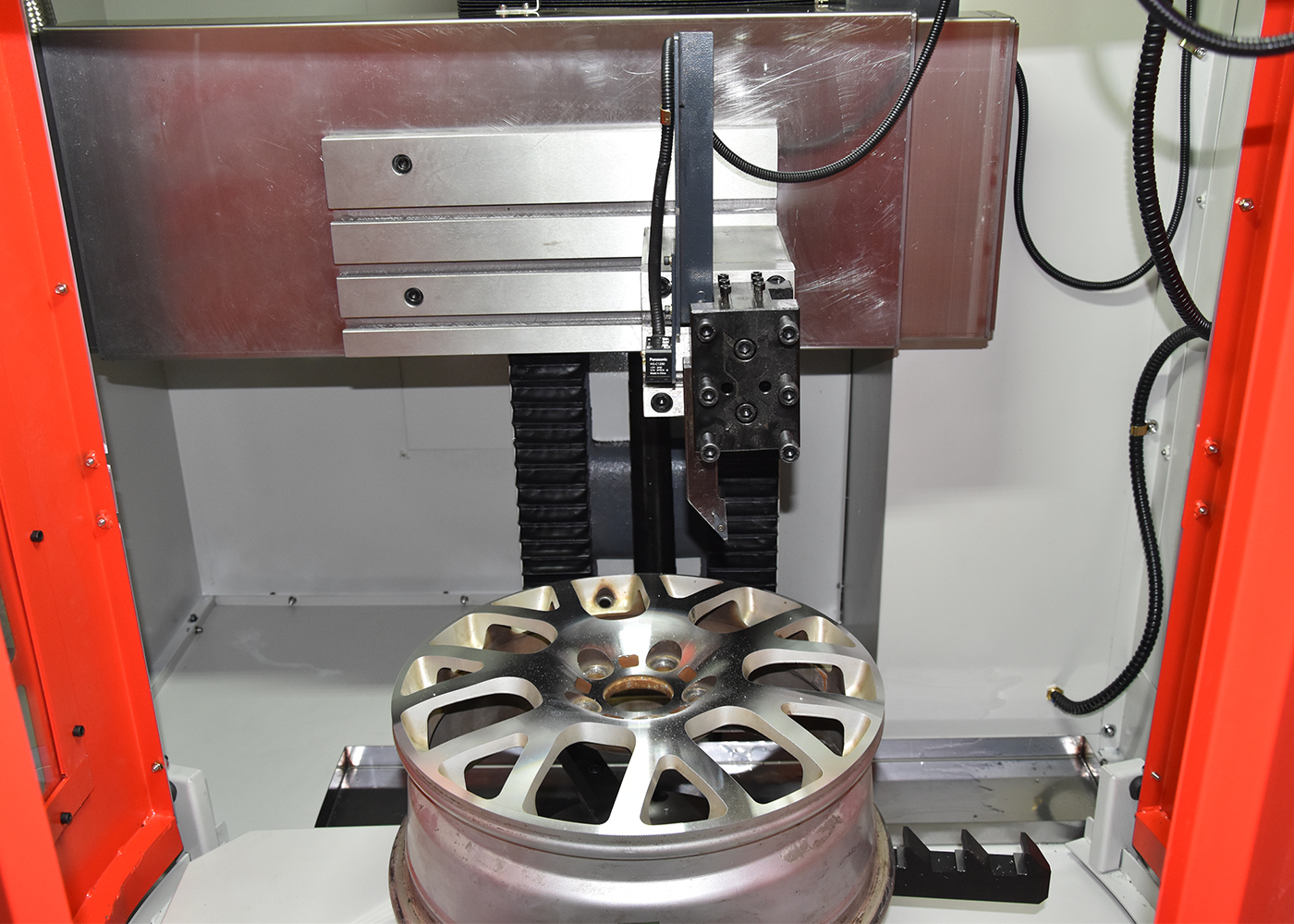

The CKL22Q and CKL35 alloy wheel repair lathe models incorporate advanced probe systems for meticulous damage assessment. For an even more efficient evaluation, operators can opt for a laser measurement system, which expedites the repair process with unparalleled accuracy.

Robust Construction for Enduring Performance

HAISHU’s commitment to durability is evident in the wheel CNC lathe’s construction, featuring high-precision spindle units and robust X and Z-axis linear guides. This solid build guarantees that the CKL22Q/CKL35 series can consistently deliver exceptional results, even under the rigors of daily wheel machining.

Optimizing Wheel CNC Machine Operations

Effective Cooling and Debris Management

Innovative cooling systems in the HAISHU wheel repair CNC vertical lathe mitigate thermal deformation, while air guns efficiently clear away debris. This ensures a clean working environment and maintains the high standards of each wheel repair job.

Emphasizing Safety and Simplified Maintenance

Safety features such as warning lights and an automatic lubrication system are integral to the HAISHU wheel repair machines. These elements not only promote a safer work environment but also facilitate easy maintenance, which translates to less downtime and greater productivity.

HAISHU: A Leader in Wheel Repair Excellence

Partnering with the Automotive Elite

HAISHU has earned global recognition by partnering with leading automotive brands, ensuring that our wheel repair CNC vertical lathe meet the demanding standards of industry experts. This makes HAISHU the preferred partner for professional wheel repair services.

Custom Solutions for Every Wheel Repair Need

Understanding the diverse demands of the wheel repair industry, HAISHU offers customizable solutions with our alloy wheel repair lathes. Whether it’s minor cosmetic fixes or complete wheel restorations, the CKL22Q and CKL35 models deliver top-notch results tailored to each client’s specific needs.

In conclusion, the HAISHU CKL22Q and CKL35 series stand at the forefront of wheel repair technology. These wheel repair CNC vertical lathe combine precision, efficiency, and versatility, ensuring that your business remains ahead in the competitive wheel repair market. With HAISHU’s advanced machinery at your disposal, your workshop can confidently meet and exceed the expectations of even the most discerning customers.