Introduction: The Importance of Choosing the Right Wheel Repair Lathe UK

When precision meets efficiency in wheel refurbishment, wheel repair lathes are the linchpin of automotive care. This guide highlights the criticality of choosing the correct type of probe—laser or contact—for optimal functionality of a wheel CNC machine, ensuring meticulous wheel hub restoration.

What is a Wheel Repair Lathe UK?

A wheel repair lathe UK, specifically designed for the automotive repair industry, is engineered to address and refine wheel hub imperfections. Whether it’s a wheel repair machine addressing minor abrasions or a full-fledged wheel CNC machine handling severe deformities, the goal is consistent: to restore the wheel hub to its factory-grade condition, thus safeguarding the vehicle’s performance and aesthetics.

Core Functions of Wheel Repair Machines:

- Rectifying Deformations: vertical Wheel repair lathes excel in realigning deformed wheel hubs, ensuring a smooth and balanced drive.

- Scratch and Damage Removal: Wheel repair machines are adept at eliminating surface scratches, contributing to the wheel’s visual and structural integrity.

- Dimensional Precision: Advanced wheel CNC machines reshape and cut wheel hubs to precise dimensions, conforming to strict industry standards.

- Surface Finishing: High-end lathes also perform surface treatments to deliver a comprehensive wheel refurbishment experience.

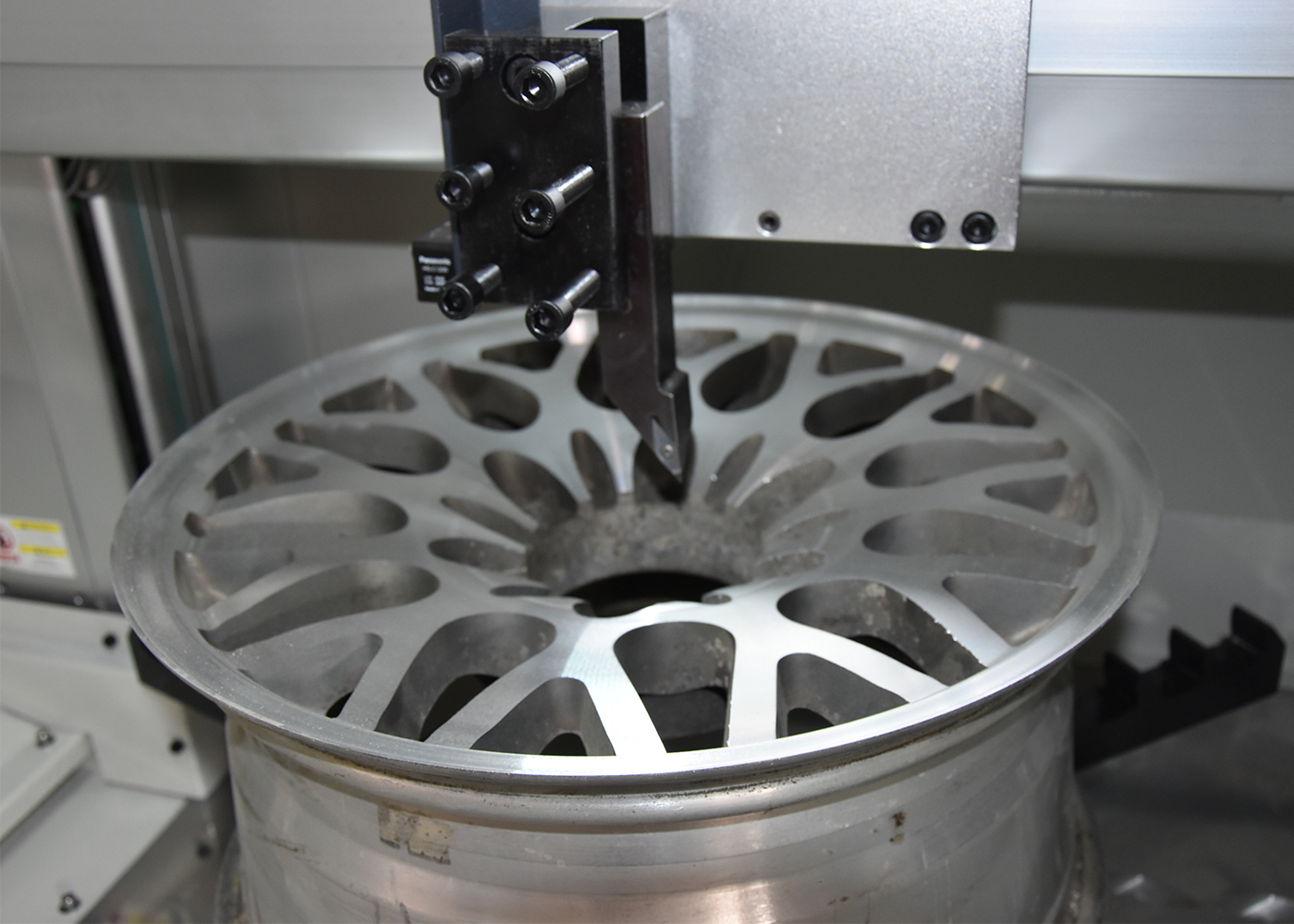

- Accurate Damage Assessment: Equipped with cutting-edge probes, these machines provide detailed measurements for precise calibration during the repair process.

Why Are Probes Essential for Wheel Repair Lathe UK?

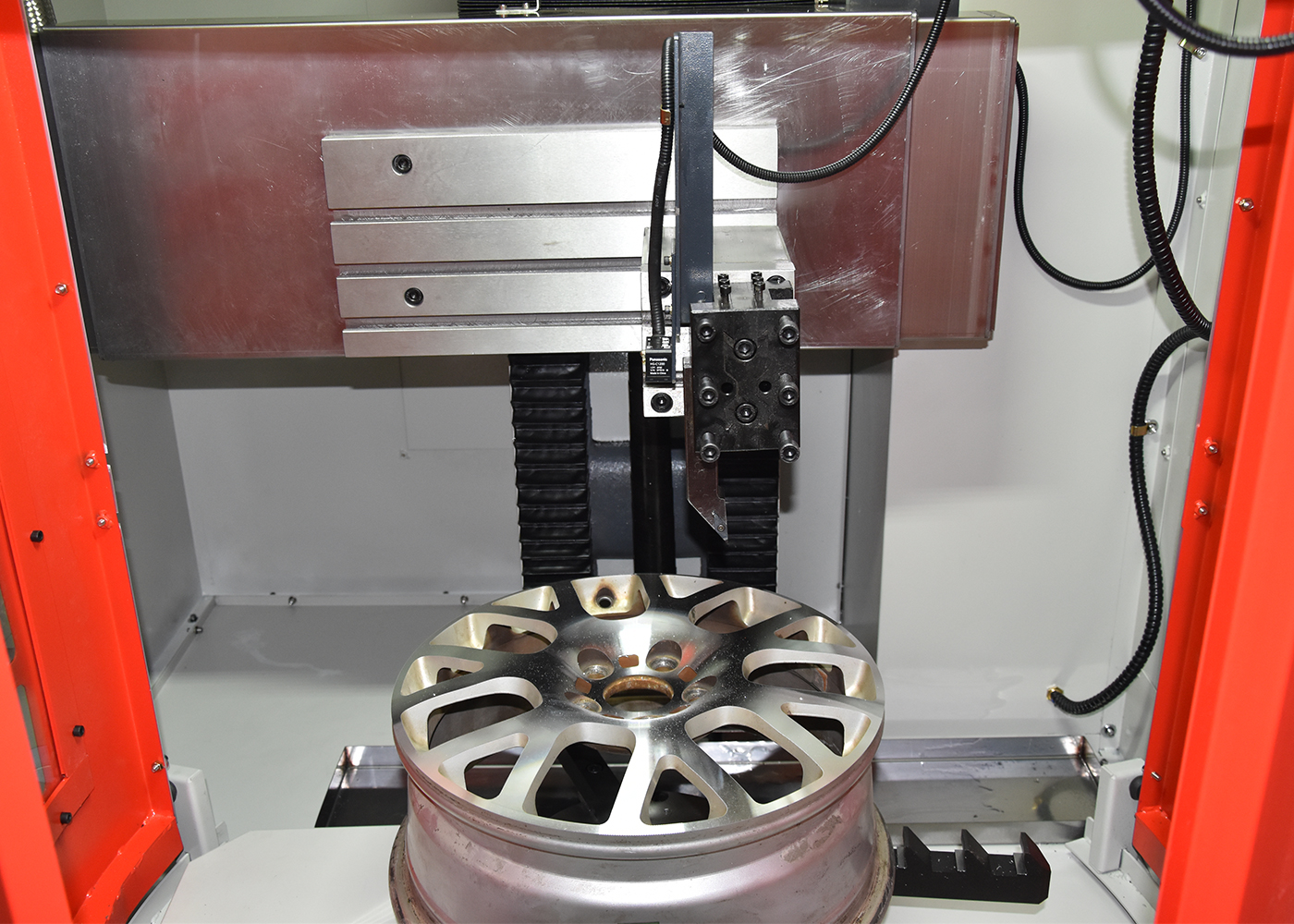

Probes are fundamental in the wheel repair process, enabling wheel CNC machines to detect and adapt to each wheel’s unique contours and damages.

Enhancing Refurbishment with Probes:

- Accurate Diagnostics: Probes ensure precise measurements, essential for the wheel repair lathe to effectively restore the hub.

- Automated Processes: In CNC lathes, probes facilitate automated adjustments, enhancing repair accuracy and reducing manual labor.

- Quality Assurance: The use of probes in wheel repair machines correlates with the consistency and quality of the refurbishment, meeting OEM standards.

- Minimizing Errors: Automated probing systems greatly reduce the potential for human error during the refurbishment process.

- Efficiency Gains: Probes expedite the scanning and measurement phase, crucial for service centers that prioritize turnaround time.

How Do You Choose Between Laser and Contact Probes for Wheel Repair Lathe UK?

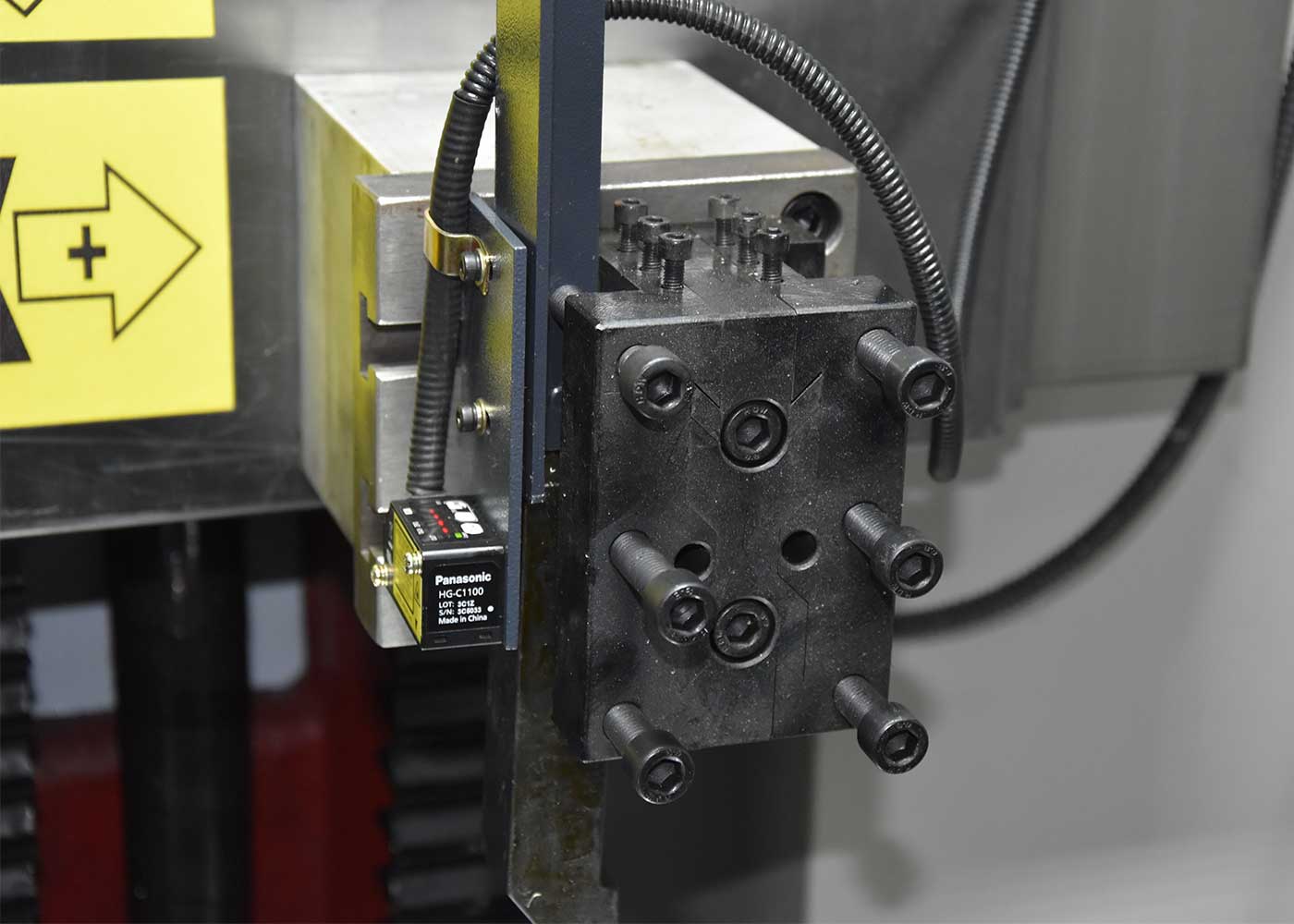

The choice between contact and laser probes is pivotal in fine-tuning the refurbishment process. Contact probes, in direct touch with the wheel hub, offer unparalleled accuracy and are a mainstay in traditional wheel repair lathes. Laser probes, on the other hand, provide rapid and non-invasive measurements, lending themselves to a more streamlined operation in modern wheel CNC machines. The right probe choice can significantly enhance the performance of wheel repair machines, impacting the efficiency and quality of the service provided.

Laser Probes in Wheel CNC Machines:

- Advantages: Non-contact measurement ideal for delicate surfaces, rapid operation, high precision.

- Limitations: Higher initial costs, and sensitivity to dust and debris.

Contact Probes in Wheel Repair Machines:

- Advantages: Cost-effective, durable, and versatile for flat hubs.

- Limitations: Physical contact risk of damage, slower operation.

Why Is Precision Key in Wheel Repair Lathe UK?

Precision in hub refurbishment is critical for multiple reasons, especially when utilizing advanced mobile wheel repair lathes and wheel CNC machines.

Importance of Precision:

- Safety: Ensures the hub can distribute the vehicle’s weight evenly, preventing imbalance and vibration.

- Performance Maintenance: Restores the hub’s performance and durability, minimizing uneven tire wear and maintaining vehicle handling.

- Aesthetics: Ensures the refurbished hub looks as good as new, enhancing the vehicle’s overall appearance.

- Cost-Effectiveness: Avoids high costs associated with hub replacement, and reduces material waste.

- Value Retention: Maintains or enhances the vehicle’s resale value.

- Compatibility: Ensures exact compatibility with other vehicle components, reducing additional component wear.

Incorporating the appropriate probe technology into a wheel repair lathe UK is a strategic move toward optimizing a service provider’s operations. With a well-balanced approach to probe selection, automotive service centers can expect to climb the search engine ranks, drawing in customers looking for top-tier wheel refurbishment services.