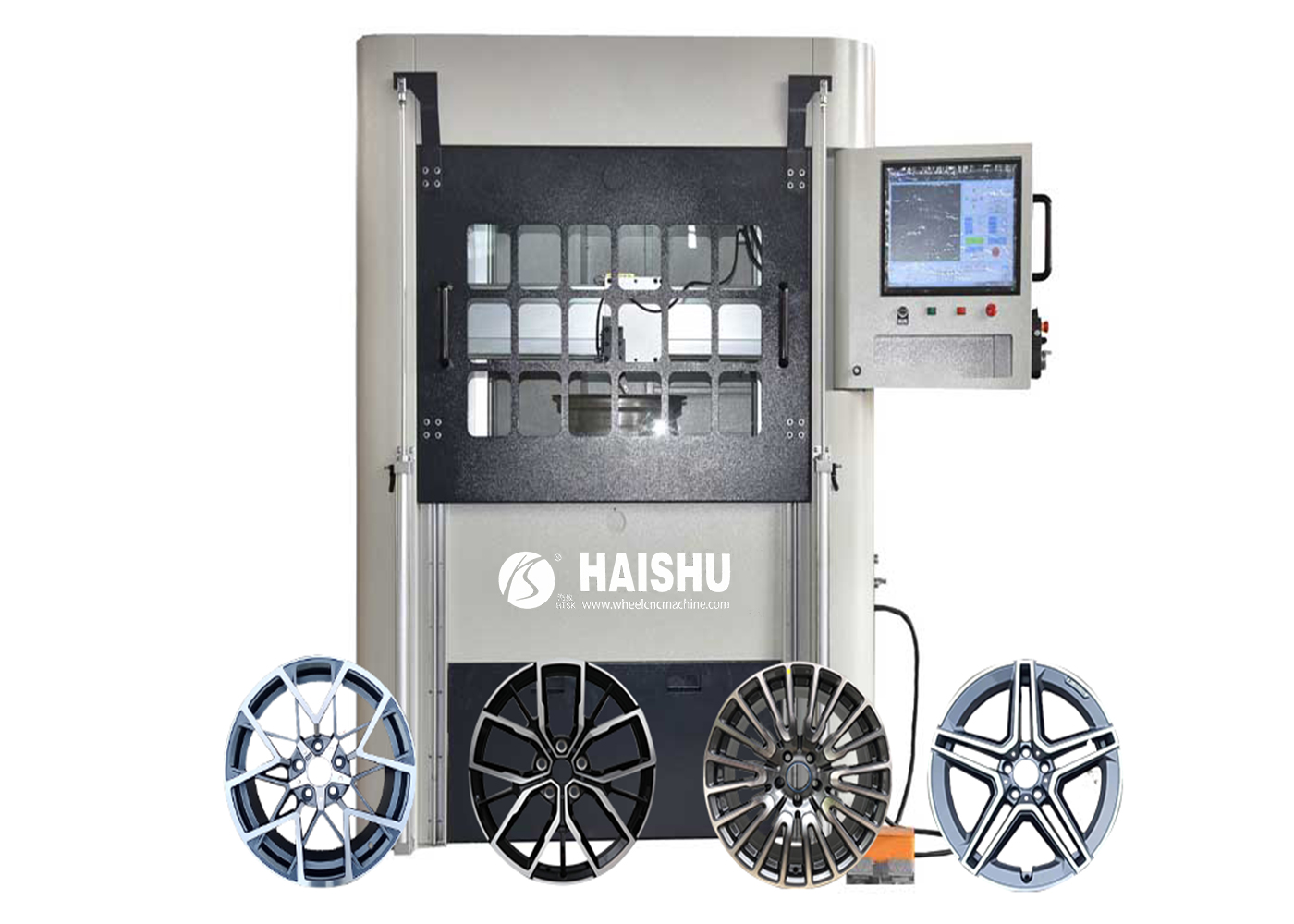

Elevate Your Wheel Repair Services with the HAISHU CKL-35 Vertical Wheel Repair Lathe Machine

In the realm of automotive maintenance, the HAISHU CKL-35 Vertical Wheel Repair Lathe Machine stands out as a paragon of innovation, designed to meet the complex needs of alloy wheel machining. This wheel CNC machine, widely acclaimed in automobile factories and repair shops, is synonymous with reliability and top-tier performance.

Unmatched Professionalism and Functionality

The wheel repair lathe machine offers an unparalleled blend of strong professionalism and multiple functions, ensuring good quality and high-cost performance. Its wide processing range is suitable for a variety of wheel repairs, with high efficiency, fast clamping, and user-friendly operation. The HAISHU CKL-35 brings all these coveted traits into a single machine, delivering timely service and exceptional results.

Sturdy Vertical Structure for Diverse Wheel Sizes

The vertical structure of the wheel repair lathe machine is engineered for stability and precision. Featuring a moving turret and crossbeam, alongside a robust linear guide, pneumatic doors, spindle unit, and double column drive, it caters to the repair of wheels from small passenger cars to larger commercial vehicles. With a maximum repair size of 35 inches, the HAISHU CKL-35 is perfect for aluminum wheels on cars, SUVs, buses, and trucks.

Customized Control System for Streamlined Operations

The control system of the wheel repair machine is a standout feature, optimized for easy operation with an LCD touch screen. This system addresses the shortcomings of conventional CNC systems, offering complete functions and a professional interface. With the flexibility to choose languages and customize content, it caters to a global user base.

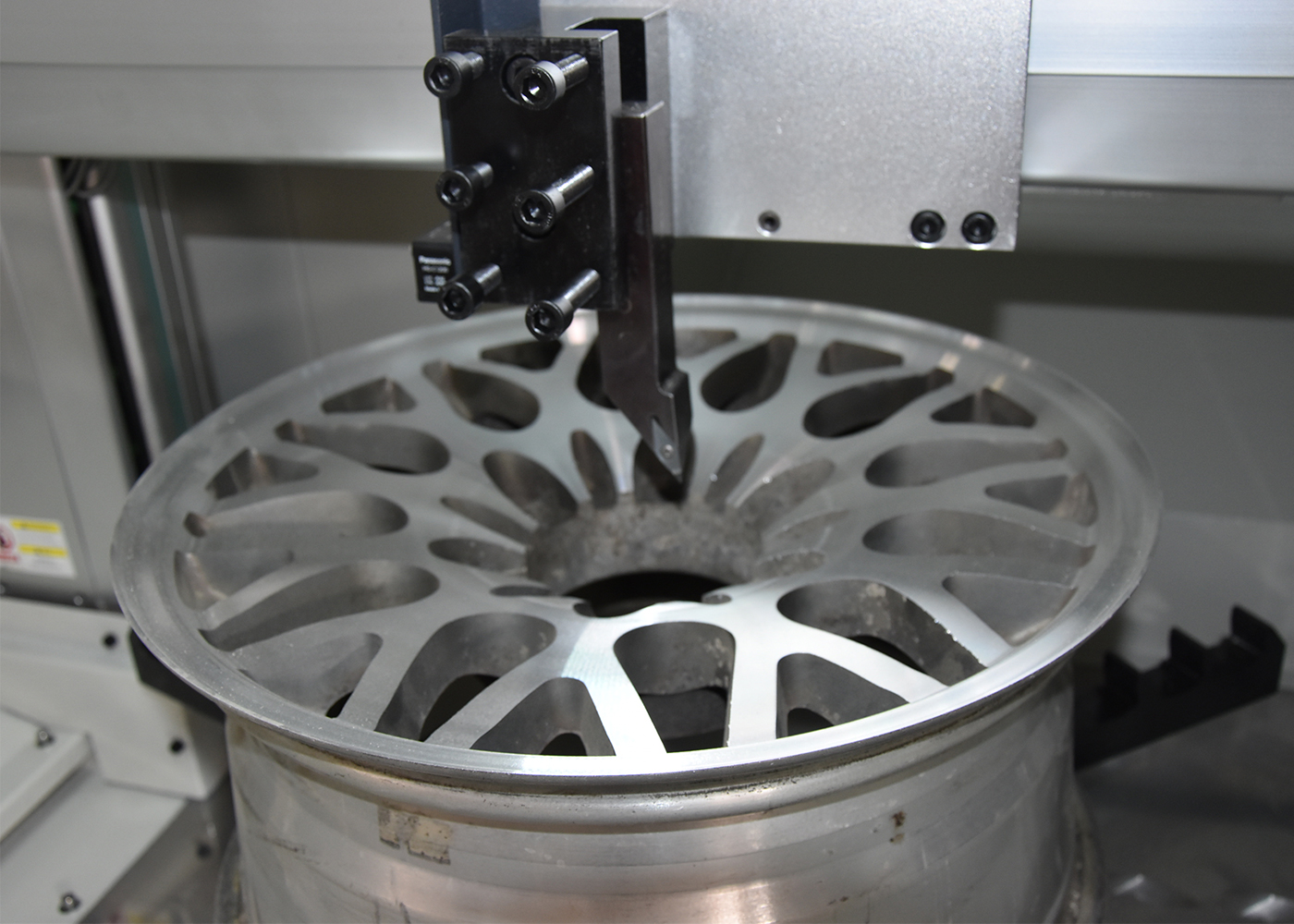

Advanced Measurement Techniques for Precision

This rim straightening machine doesn’t just offer traditional probe measurement; it is equipped with laser measurement for rapid curve scanning and point measurement. This technology enhances repair efficiency and accuracy, allowing for the repair of large depth wheel surfaces without the constraints of probe depth dimensions or wear.

Automated Program Optimization for Flawless Results

With the HAISHU CKL-35, program optimization is no longer a manual task. The wheel CNC machine’s computer system automatically optimizes the wheel surface curve replication and design, ensuring that every wheel repair or beautification is executed flawlessly. This level of optimization, not possible with general-purpose systems, can be a significant advantage in delivering superior wheel repair services.

Teaching Function for Expanded Repair Capabilities

The wheel repair lathe machine boasts a teaching function that transcends the basic repair process. Operators can manually pinpoint areas on the wheel surface for repair, and the system will automatically perform the task following the set path. This function greatly expands the capabilities of the machine, allowing for detailed and specific wheel repairs that go beyond what standard CNC systems can achieve.

Quick and Versatile Wheel Clamping

Efficiency is key in wheel repair, and the CKL-35 ensures it with special wheel fixtures that facilitate quick and easy clamping. Whether positioning by the rim or the center hole, this feature streamlines the repair process and saves valuable time.

Continuous Development and After-Sale Support

HAISHU is dedicated to the ongoing development of the wheel repair lathe machine’s special system, offering free upgrades after the sale. Equipped with a cable socket for online connectivity, the CKL-35 allows for remote operation, debugging, teaching, and technical services, ensuring that users always have access to the latest advancements and support.