Introduction

Wheel Repair Lathe Questions and Wheel CNC Machine Insights: Dive into our extensive guide to answering your most pressing questions about wheel repair lathes and CNC machines. Learn the nuances of wheel restoration, understand the technical specifications, and discover how to leverage these sophisticated tools for your automotive repair business. Our article provides step-by-step troubleshooting advice, tips for maintaining your equipment, and expert recommendations on choosing the right lathe for your needs. Whether you’re dealing with a simple rim fix or a complex refurbishing project, our guide ensures you know how to use your wheel CNC machine with confidence. Enhance the longevity and performance of your wheels with our comprehensive Q&A resource tailored for both novices and seasoned technicians.

1. What is a Wheel Repair Lathe?

In the railway industry, a wheel repair lathe is a crucial tool used to refurbish and reprofile rolling stock wheels, ensuring optimal performance and safety. This specialized lathe operates without the need to dismount the wheelset from the vehicle, minimizing downtime. Installed in a maintenance pit beneath a dedicated track, the wheel repair lathe allows efficient reprofiling of wheelsets by moving the vehicle along the track. Discover the benefits of this cutting-edge technology in enhancing rolling stock longevity and reliability.

2. Is Wheel Repair Worth it?

One of the main factors driving the preference for rim repair among drivers is the significant cost savings it offers. Unlike rim replacement, which involves expenses for both the new rim and installation, rim repair is a more budget-friendly option. With a flat service fee, drivers can enjoy the same excellent results while keeping their expenses in check. Discover the affordable and reliable solution of rim repair to restore your rims without breaking the bank.

3. What is a wheel smart repair?

The wheel repair process focuses on revitalizing the damaged area, achieving results comparable to a diamond-cut finish. Through a meticulous approach, the damaged metal is worked on progressively, followed by polishing to restore its original appeal. To seamlessly blend the repaired section, chrome paint is carefully applied, creating a cohesive appearance. Finally, a protective lacquer is applied, safeguarding the wheel against future damage. Experience the precision and transformation of your wheels with our effective and comprehensive wheel repair price

4. What is a wheel repair lathe used for?

A wheel repair lathe is a specialized tool used in the automotive and railway industries to reprofile and refurbish wheels. By utilizing this lathe, wheelsets can be repaired without the need for dismounting from the vehicle. It is an efficient method for restoring damaged wheels, enhancing their performance and safety. Discover how a wheel repair lathe can restore the integrity of wheels and prolong their lifespan.

5. What is a wheel lathe used for?

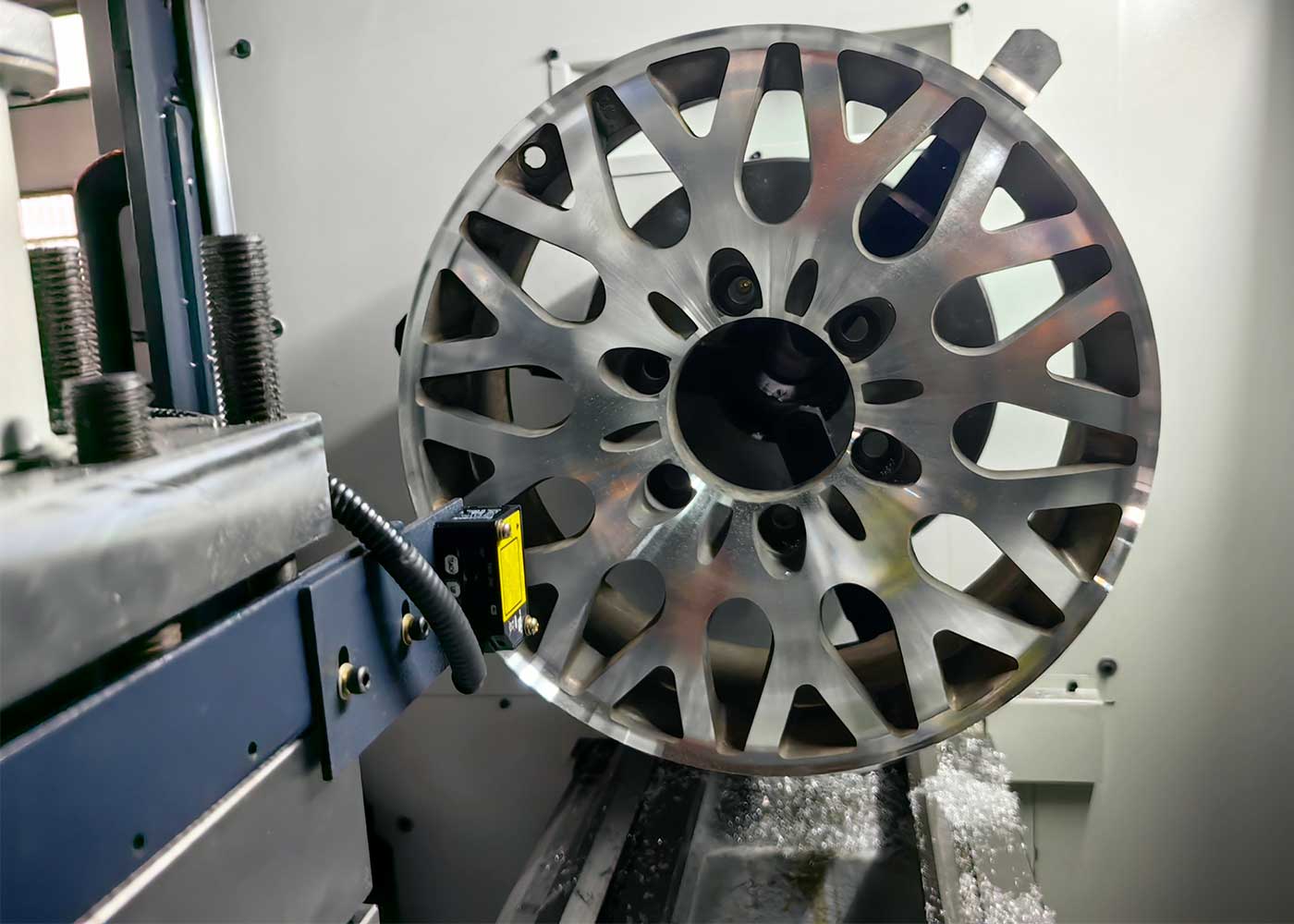

Wheel lathe machines are essential devices used for repairing and cleaning damaged wheels. They are compatible with various wheel models available in the market. Notably, alloy wheels, known for their intricate designs, can be effectively worked on with wheel lathe machines. Discover the versatility and effectiveness of wheel lathe machines in restoring and enhancing the appearance of wheels while addressing any damage or imperfections.

6. How long does it take to repair a wheel?

Typically, wheel repairs can be completed within approximately 15 minutes per wheel. The best part is that in many cases, you don’t need to remove the wheels from your car. The wheel repair process can be conveniently carried out while the wheel is still mounted on the vehicle, saving you time and hassle. Discover the efficient and convenient wheel repair service that keeps your wheels looking their best.

7. Are repaired wheels safe?

Properly repaired wheels offer long-lasting and safe performance for countless miles. It’s crucial to select a wheel repair professional who follows a stringent repair process. Before straightening and repairing, reputable professionals conduct thorough inspections of the wheels. This ensures any underlying issues are identified and addressed, guaranteeing optimal results. Choose a trusted wheel repair service that prioritizes quality inspections and meticulous repairs for reliable and safe wheel performance.

8. Can a damaged wheel rim be repaired?

Wondering if a bent rim can be repaired? In most cases, a skilled tire professional can successfully restore the shape of your rim. However, for more severe damage, a complete replacement might be necessary. Don’t worry, trusted experts can assess the condition of your rim and provide the appropriate solution, ensuring safe and reliable performance. Discover reliable rim repair and replacement services for a smooth and worry-free driving experience.

9. Is alloy wheel repair safe?

When an alloy wheel rim develops a crack, it can lead to air leakage and affect tire pressure. People often question the safety of a cracked rim, but the answer is YES! The welding process effectively seals the crack and restores strength to the rim. With professional repair, you can confidently drive knowing that your rim is safe and secure. Discover reliable alloy wheel crack repair services for peace of mind on the road.

10. How much does wheel refurb cost?

The cost of refurbishing alloy wheels typically ranges from £50 to £120 on average. When deciding to refurbish your alloy wheels, factors such as the extent of damage, the type of car you drive, the model’s premium status, and other considerations need to be taken into account. Evaluate these factors to determine the appropriate budget for refurbishing your alloy wheels and restoring their appearance.

11. How many times can you repair alloy wheels?

While diamond-cut alloy repair and refurbishment can be highly effective, it’s important to note that this process should not be repeated excessively. Ideally, it is recommended to limit diamond cut repairs to 2-3 times. Excessive removal of layers can result in a thinner surface, making it more susceptible to cracks. Prioritize proper maintenance and avoid over-repairing to ensure the longevity and durability of your alloy wheels.

12. How bad is a cracked wheel?

Extensive cracks in wheels can be a safety hazard, leading to sudden air loss in tires. Even a small crack can expand gradually and may only require a minor impact to widen. A blowout caused by a crack can be highly dangerous, resulting in loss of vehicle control and potentially causing severe accidents. Prioritize regular inspection and timely repair of cracks to ensure safe and worry-free driving.

13. Is it worth repairing alloys before selling?

Many car owners view repairing scratched alloys as an additional expense on top of purchasing a new vehicle. However, if you’re considering selling your car, getting the alloys fixed can be a wise investment. By addressing the scratches, you eliminate potential buyers’ hesitation and increase the chances of a successful sale. Ensure your car stands out positively in the market by fixing those alloy scratches and attracting confident buyers.

14. Is wheel refurbishment worth it?

Frequently asked, “Is it worth refurbishing my alloys?” Our resounding answer is yes. Whether for damage repair or enhancing the value of your car, we strongly advise getting your alloys refurbished sooner rather than later. Don’t delay in restoring the appeal and value of your vehicle with professional alloy refurbishment services.