Revolutionizing Wheel Refurbishment: The Wheel Scratch Repair Lathe CK6160Q

Redefining Efficiency with Advanced Wheel CNC Machine Technology

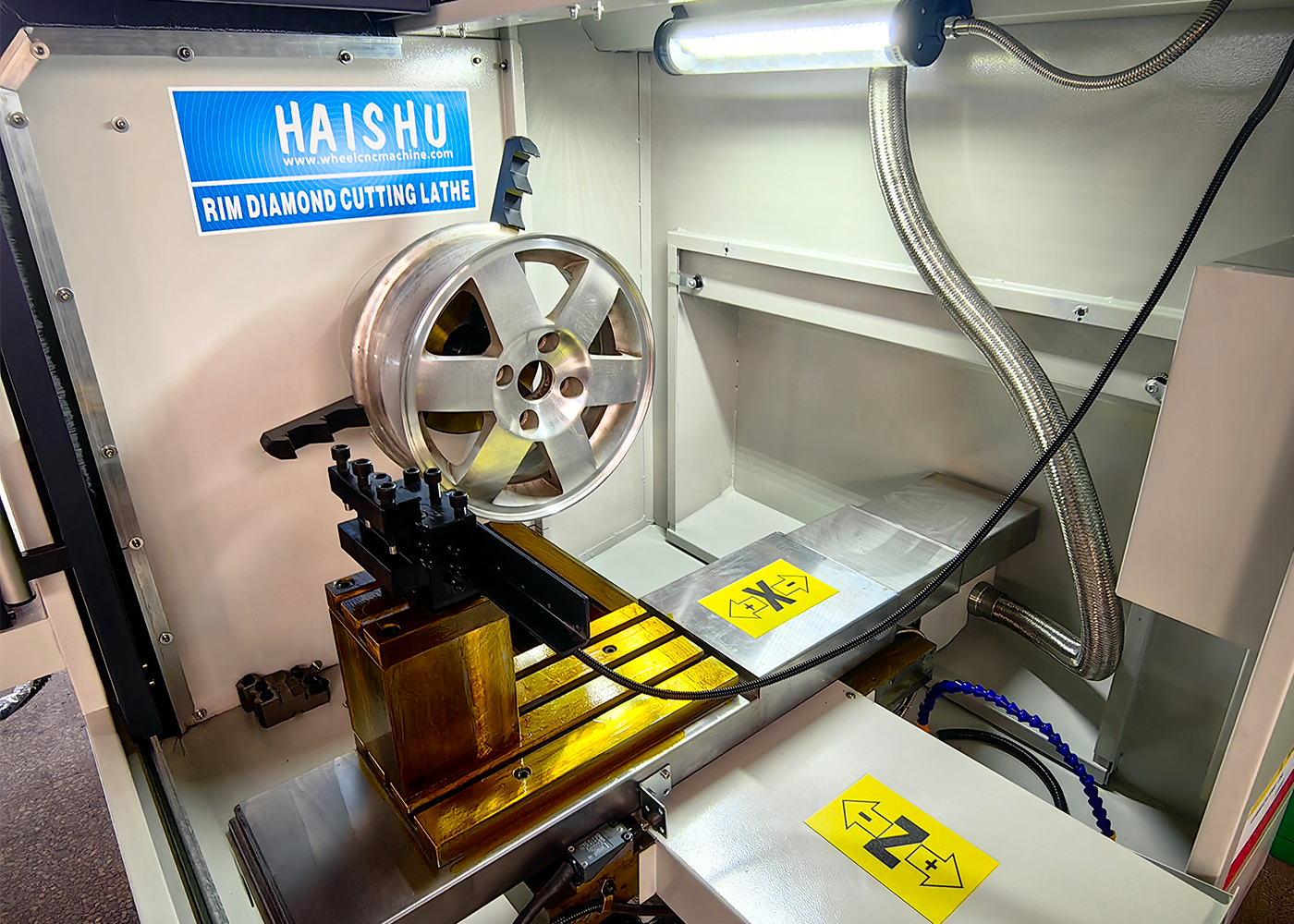

In the realm of automotive aesthetics and functionality, the condition of a car’s wheels is paramount. As an increasing number of modern vehicles come equipped with diamond-cut alloy wheels, the demand for meticulous wheel refurbishment services is on the rise. The Wheel Scratch Repair Lathe CK6160Q emerges as a market leader in this niche, offering a sophisticated solution for repairing alloy car wheels up to 24 inches in diameter.

Compact Powerhouse: CK6160Q’s Superior Features

The CK6160Q’s self-developed CNC system is a marvel of engineering, boasting high efficiency within its compact structure. The user-friendly touchscreen interface simplifies operations, making it accessible to technicians of varying skill levels. With the growing epidemic of wheel damage from curbs and everyday wear, this wheel repair lathe provides a swift and cost-effective restoration to a showroom finish. A standard 20-inch wheel can be rejuvenated in a mere 20 minutes, highlighting the machine’s impressive performance.

Alloy Wheel Repair Machine: A Versatile Solution

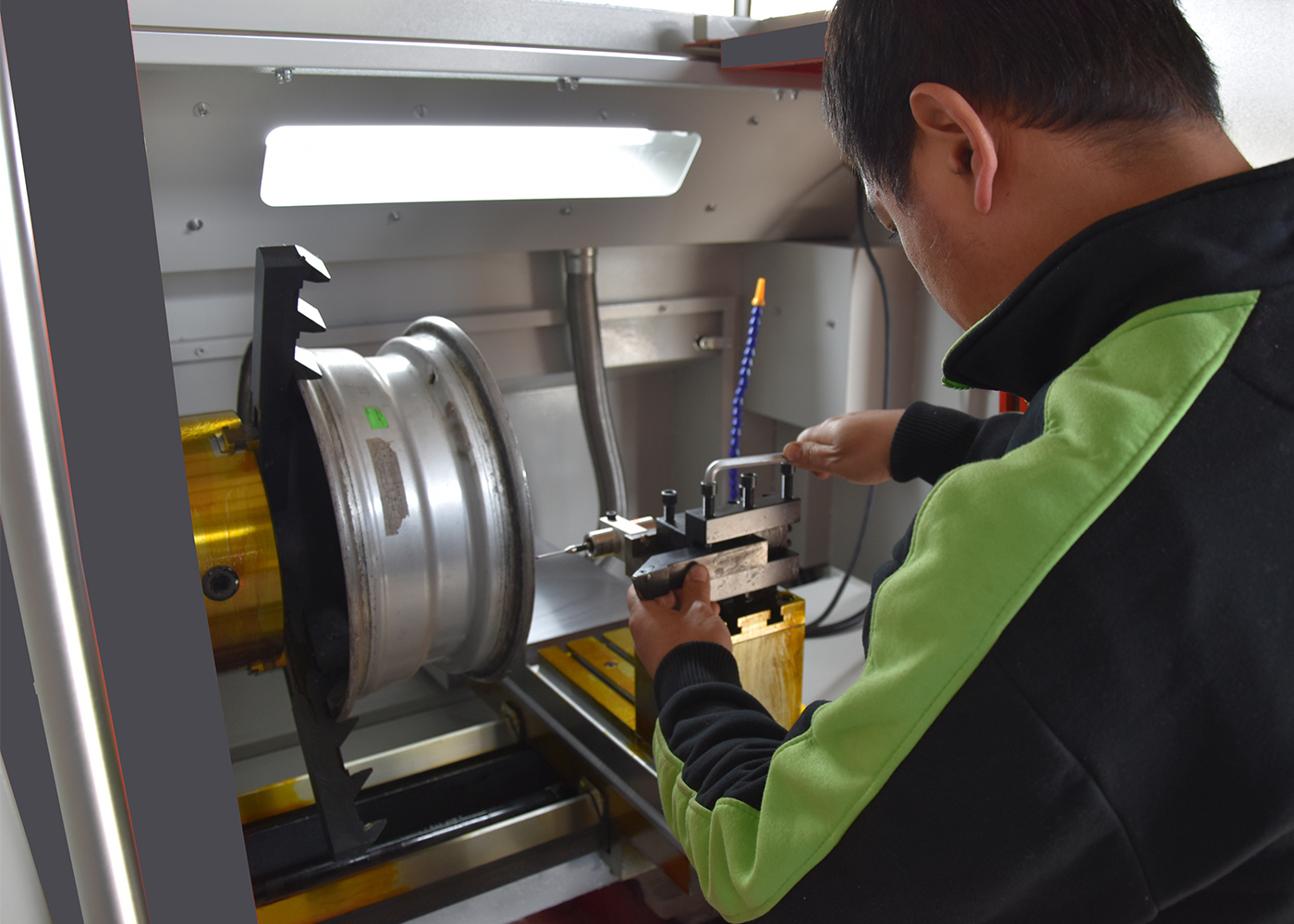

This alloy wheel repair machine is not limited to standard repairs. It features the flexibility of using either laser scanning or probe click measurement, ensuring that each repair is tailored to the wheel’s specific needs. The data from each wheel is stored automatically, allowing for easy retrieval and consistent repairs. The CK6160Q’s software is a product of independent development, which means it’s been refined to automatically optimize each machining program.

Seamless Operation with the Wheel CNC Machine

The CK6160Q wheel CNC machine is not just about delivering excellent results; it’s also designed for ease of use. Its touch screen operation and multi-language system interface ensure that the machine can be adopted globally without language barriers. The X/Z axis measurement capability allows for precise machining of the wheel surface and its circumference.

The CK6160Q: A Model of Precision and Speed

Wheel Processing Made Effortless

The vertical wheel repair lathe CK6160Q is engineered to perform with precision and speed. The automatic precise and fast wheel processing eliminates the manual guesswork and reduces the time spent on each wheel. The diamond-cutting tool ensures a smooth finish, rivaling the original manufacturing standards.

Enhancing Operations with a Vertical Wheel Repair Lathe

The vertical orientation of the CK6160Q wheel repair lathe is a feature that sets it apart from conventional models. This design not only saves on floor space but also improves accessibility and simplifies the process of wheel repair.

Long-Lasting Performance with Automatic Lubrication

To ensure the longevity and consistent performance of the CK6160Q, an automatic lubrication system is integrated. This system maintains the machine’s parts, reducing the wear and tear associated with frequent use.

Expanding the Horizons of Wheel Repair

Teaching Function: Empowering Technicians

One of the standout features of the CK6160Q wheel repair machine is its computer-based teaching function. This feature simplifies the learning curve for operators, enabling them to master the machine’s functionality and repair processes quickly.

Alloy Wheel CNC Machine: A Customizable Asset

Recognizing the diverse needs of the market, the CK6160Q alloy wheel CNC machine offers customization options. This flexibility ensures that each machine can be configured according to the specific requirements of clients, making it a versatile tool for any wheel repair business.

Haishu Machinery: Pioneers in Wheel Repair

A Commitment to Excellence

Haishu Machinery stands at the forefront of the wheel repair industry, dedicated to the research and development, manufacturing, and sales of the Wheel Scratch Repair Lathe CK6160Q. The company has carved a niche for itself by partnering with leading American automotive maintenance companies and introducing advanced wheel repair technologies and processes.

A Vision of Green Innovation

As a proponent of environmental sustainability, Haishu Machinery prides itself on being a green enterprise. Through repairing and refurbishing old wheels, the company transforms waste into valuable resources, contributing to a circular economy.

In summary, the Wheel Scratch Repair Lathe CK6160Q is a testament to Haishu Machinery’s innovation and dedication to quality. It is an indispensable tool for automotive repair shops looking to provide top-notch wheel refurbishment services. With its advanced features and customizable options, the CK6160Q is set to become the standard in the wheel repair industry.