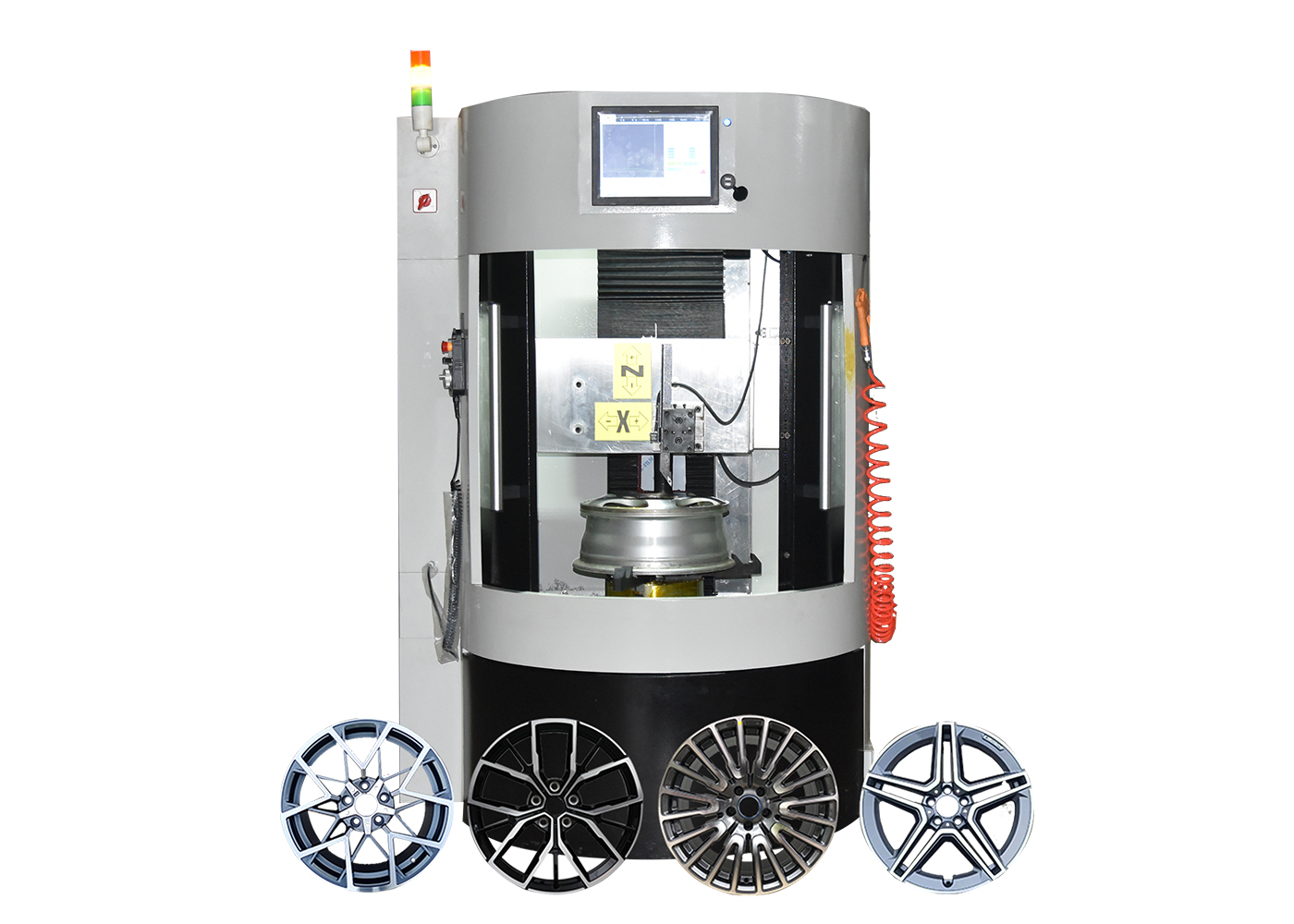

Advanced RSM595 Wheel Shaping Repair Machine

Precision Wheel Repair with RSM595

The RSM595 Wheel Shaping Repair Machine stands at the forefront of wheel restoration technology. Expertly designed to rectify distortions, depressions, and deformations, this wheel CNC machine is an essential tool for restoring aluminum alloy wheels to their pristine condition. Its automated capabilities ensure a consistently high standard of repair for wheels with diameters ranging from 10″ to 26″.

Effortless Operation and Superior Results

Taian Haishu’s new wheel shaping repair machine excels at correcting deformations on any aluminum alloy wheel up to 26 inches. It masterfully handles the correction of weld edges and intricate processing tasks. The integrated hydraulic unit simplifies operation without compromising the wheel’s molecular integrity or mechanical properties. Advanced heat treatment and artificial aging techniques are employed to quickly revert wheels to their original shape.

Unmatched Versatility and Efficiency

The RSM595 is equipped with a variable speed function, ranging from 0-300r/min, enhancing the efficiency of tasks such as offset detection, positioning, plastic repair, lathe cutting, and mirror polishing. This wheel repair lathe is not just a tool but a complete solution for aluminum alloy wheel shaping, correction, edge processing, and surface planing. As the most advanced piece of equipment in the realm of CNC wheel lathe technology, the RSM595 is an indispensable asset for any professional in the wheel repair industry.

Essential Maintenance for Optimal Performance of RSM595 Wheel Repair Machine

Regular Maintenance: The Key to Longevity

The RSM595 Wheel Repair Machine is a cornerstone of efficiency in automotive wheel repair. To ensure its longevity and optimal performance, daily cleaning and maintenance are crucial. Users are advised to adhere to the guidelines specified in the operation manual for routine upkeep.

Daily and Monthly Checkpoints

Before commencing any cleaning or maintenance work, it is imperative to turn off the main power and disconnect the machine from its power source. Daily, the turntable and lathe require cleaning and lubrication to operate smoothly. Monthly checks should be conducted on the hydraulic system to verify oil levels, and a thorough tightening of the lathe parts screws is recommended to maintain structural integrity.

Biannual Maintenance and Comprehensive Inspection

Every six months, bearings demand greasing to ensure fluidity in movement, accompanied by a comprehensive machine inspection. This biannual check is vital to preemptively address any potential issues, thereby averting downtime and costly repairs.

Advanced Features of the RSM595 Wheel Shaping Repair Machine

Precision Wheel Restoration

The RSM595 is engineered to masterfully straighten and mill imperfections on car rims ranging from 10″ to 26″ in diameter. Its precise capabilities make it an indispensable asset for any wheel repair workshop.

Milling and Polishing Excellence

Post-welding irregularities are effortlessly milled away, offering a seamless and smooth finish to any wheel (note: welding machine not included). For those seeking an additional touch of perfection, an optional electrical polisher attachment is available to ensure a pristine, smooth rim surface.

Robust Construction

Boasting a hydraulic cylinder pressure of 10,000 kg, the RSM595 is built to handle the demands of busy repair shops without faltering, providing relentless service and reliability.

Taian Haishu Machinery: The CNC Pioneers

Dedication to Innovation and Quality

Since 2001, Taian Haishu Machinery Co., Ltd. has been at the helm of CNC machine design and manufacturing, offering comprehensive automobile wheel production and repair solutions to a global clientele. With a team of over 30 specialized experts and a state-of-the-art 12,000 square meter facility, our commitment to innovation, simplicity, and efficiency is unwavering.

A Rich Tapestry of High-Quality Products

Our product portfolio is expansive, featuring the wheel CNC machine, wheel repair lathe, brake drum lathe, and custom CNC solutions. We pride ourselves on our rigorous approach to CNC software development, structural design, process planning, manufacturing, and quality control.

Global Reach and Partnership Opportunities

Our esteemed clientele spans continents, with a presence in Germany, Russia, Spain, India, and beyond. As we continue to expand, we are actively seeking partners worldwide to join us in our mission to lead the industry with our advanced wheel shaping repair machines and CNC technology.