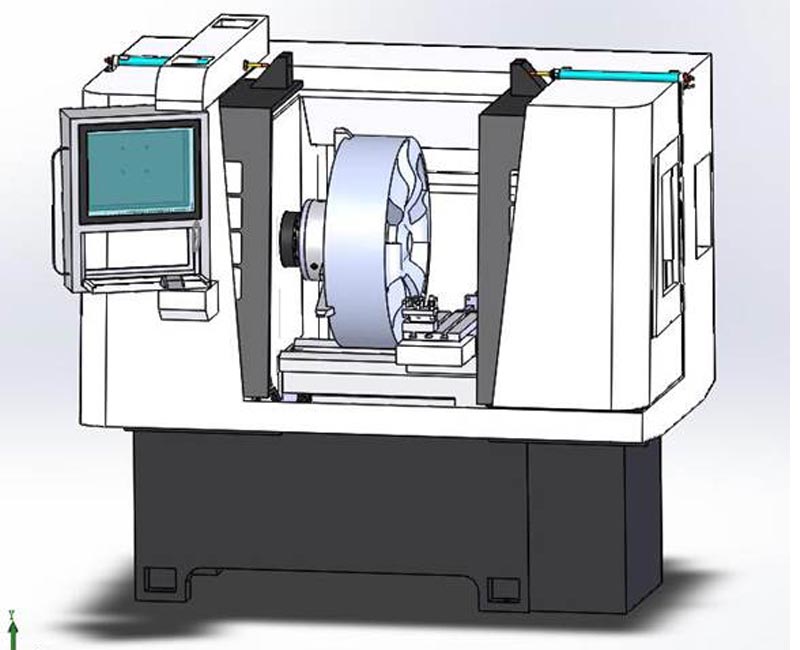

Wheel Surface Repair CNC Lathe CK6160W is a powerful CNC lathe for car wheel machining, super-finishing, and maintenance. The wheel CNC lathe has following advantages such as low rim repair cost, self-centeral chuck rims for quick installation, perfectly balanced for precise work, etc. The fully automatic system is easier to operate. Once the wheel CNC machine for car wheel repairing has automatic detection, the wheel profile is no need for you to waste time for programming. Our Wheel Surface Repair CNC Lathe has taken care of that for you. The system profile can be stored automaitcally and build up the library for a series of alloy wheels. It can greatly save your time so you can process more wheels!

The Poland customer needed a wheel repair machine, after confirming the wheel the small size, we chose the small wheel CNC lathe CK6160 for them and they wanted full protection, so he confirmed the wheel repair machine CK6160W. What they worried about was that they have never used any CNC machinery, so they were very concerned about the operation of the wheel machine. Through the remote connection, we showed the operation process of the alloy wheel lathe in detail. They are very happy with such a simple operation. Then they asked for the PI and a few days later they paid the deposit.

After the Wheel Surface Repair CNC Lathe CK6160W was completed, we sent them the wheel CNC lathe testing videos. They were very satisfied and look forward to using the machine.

Wheel Surface Repair CNC Lathe CK6160W Specifications

| Item | Unit | Specifications |

| Max Wheel Diameter | inch | 22″ |

| X-axis maximum stroke | mm | 320 |

| Main motor power | kw | 3 |

| Rial Width | mm | 260 |

| Max. workpiece length | mm | 500 |

| Wheel measuring direction | X, Z | |

| Measuring Tool | Laser or probe (optional) | |

| Measurement method | Point measurement and quick scan | |

| Program optimization | Manual and automatic | |

| Number of wheel processing programs | rows | 100000 |

| CNC System | “HAISHU” special system (touch screen operation, 17 “screen LCD display).

Universal CNC system (key operation, 10.4 “screen LCD display) (optional) |

|

| Wheel processing | Surface, rim | |

| Machining accuracy | um | IT6~IT7 |

| Main drive form | Frequency control, servo drive (optional) | |

| Spindle speed | Factory setting 150~2800 | |

| Fast-moving feed | mm/min | X:5000 Z:8000 |

| Repeat accuracy | mm | X :0.01 Z :0.015 |

| Turret form | Fixed turret, Electric turret (optional) | |

| Section of the turning tool | mm | 25×25 |

| Machine size(L×W×H) | mm | 1900×1400×1750 |

| Net weight | kg | 1100 |

Wheel Surface Repair CNC Lathe CK6160W Features

- Diamond-Cut Wheel Machine CK6160W has the advantages of simple structure, low cost, and high-performance price ratio.

- Wheel Machine CK6160W can be selected by laser scanning or probe click measurement.

- Wheel data is automatically stored, machining program is arbitrarily called out.

- Software independent development, program automatically optimize

- Wheel processing is automatic precise and fast

- Wheel CNC Machine CK6160W is operated by a touch screen, and the system interface supports many languages.

- X / Z-axis measurement, wheel surface, and circumferential machining.

- Diamond-Cut Wheel CNC lathe CK6160W is equipped with an automatic lubrication system.

- Wheel CNC lathe CK6160W with diamond tool turning, make the wheel surface more smooth.

- Alloy Wheel Machine CK6160W has the teaching function of the computer.

- Wheel repair Machine CK6160W can be customized according to customer requirements.

About Haishu Machinery

We founded Taian Haishu Machinery Co., Ltd. in 2000 and have been solving the challenges of wheel repairing parts and surfaces for 20 years. As one of the leading manufacturers of intelligent wheel repair machines, we offer our customers a holistic repair concept for repairing various components and surfaces. With our full range of target-oriented services, we support your smooth entry into new market segments. Our many years of experience in our own workshop and close contact with our customers form the basis for our innovative system solutions. Therefore, our repair systems and wide range of products are specially tailored to practical requirements.

Our technology has been successfully used in the market for many years and is continuously further developed in daily use and passed on in our practice-oriented training courses.

We always supply the latest and innovative Wheel Surface Repair CNC Lathe for a wide range of requirements in the field of resurfacing and smart restoration. In addition, we offer our customers targeted, practice-oriented training courses with accompanying technical support.